Stabilizers of transverse stability - what is it?

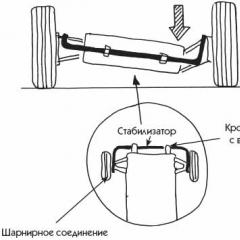

The transverse stability stabilizer is an elastic transverse strut in a car suspension, working on twisting and stretching.

In the simplest form, the transverse stability stabilizer is a steel rod p-shaped. But in modern cars, due to the compact placement of aggregates, the stabilizer give a more complex form. In the central part of the rod has a round profile.

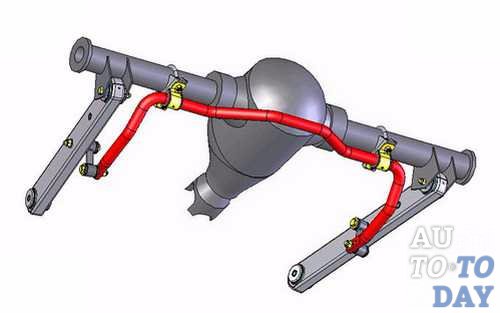

As a material, special elastic steel with good cleaner resistance is used. The middle part of the stabilizer is attached through supports to the body, subframe or car frame, and the ends to the left and right levers of the suspension or the beam of the bridge.

The transverse stability stabilizer is used both on the front and on the rear axle.

Rear and front transverse stability stabilizer - design

When the car rides a snake or turns, under the action of centrifugal forces between the elastic elements of its suspension, the redistribution of loads begins: from the outer sides of the wheels the load increases, and from the inner side the load decreases, as a result of which the car begins to roll or swing in the transverse plane.

When the car rides a snake or turns, under the action of centrifugal forces between the elastic elements of its suspension, the redistribution of loads begins: from the outer sides of the wheels the load increases, and from the inner side the load decreases, as a result of which the car begins to roll or swing in the transverse plane.

Such phenomena are very dangerous, because they can cause tilting vehicles, and can also lead to loss of control over handling car. It will help to cope with the complex task of the elastic element used in the suspension design.

Why do you need a transverse stability stabilizer, read in this article.

The value of the roll and the degree of swinging depend on the movement of the suspension, and the greater the course - respectively, more rolls. Then, to eliminate the flaws described above, this indicator needs to be reduced.

The value of the roll and the degree of swinging depend on the movement of the suspension, and the greater the course - respectively, more rolls. Then, to eliminate the flaws described above, this indicator needs to be reduced.

You can achieve a decrease in several methods:

- increase the rigidity of elastic elements, install short-spectal shock absorbers and lever limiters,

Introduce a node into the design that performs the role of an additional, elastic element in the corners.

The first two ways were the least suitable, because the comfort of the car was significantly reduced. These methods are mainly used in sports cars.

Therefore, a new elastic element was used in the suspension design - a transverse stability stabilizer, which only works when moving the wheels of one axis in different directions - one direction down, another direction up.

Therefore, a new elastic element was used in the suspension design - a transverse stability stabilizer, which only works when moving the wheels of one axis in different directions - one direction down, another direction up.

The centrifugal force when turning the car causes the rocking of its body and a tangible roll, which can cause the machine tipping. So that such situations on the road did not arise, and was invented by the stabilizer (SPU) of interest to us, which is now mounted on different types of automotive independent suspension (and the front, and rear).

It is an important element of the suspension, working on twisting, connects each other with the help of a torsion elastic part opposite wheels.

This element is not installed on the rear wheels of passenger vehicles using their own torsion beam as a suspension.

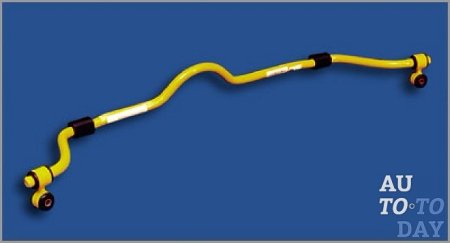

The rear and front stabilizer of transverse stability is structurally performed in the form of a round of the rod (rod) from spring steel grades. The rod is manufactured in the form of the LITER "P". Fasten it using clamps and rubber bushings, to the car body (across).

The rear and front stabilizer of transverse stability is structurally performed in the form of a round of the rod (rod) from spring steel grades. The rod is manufactured in the form of the LITER "P". Fasten it using clamps and rubber bushings, to the car body (across).

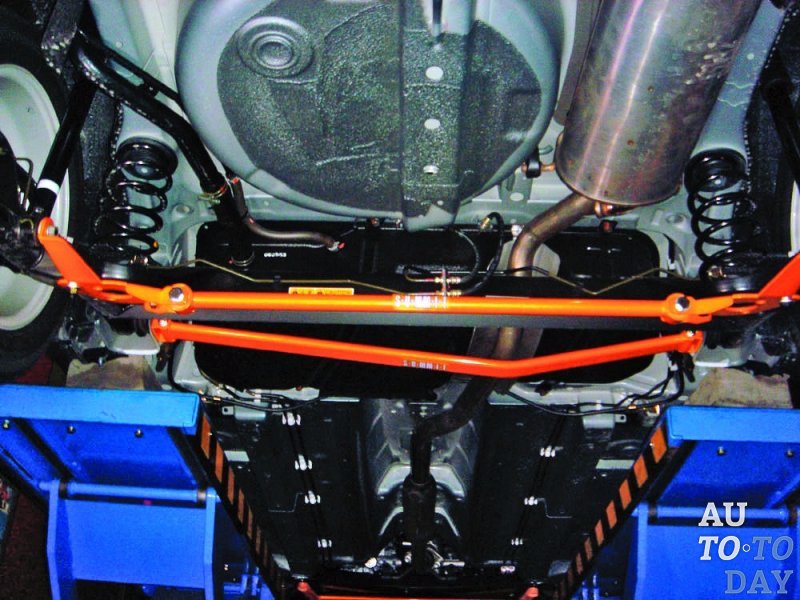

The configuration of the stabilizer can be very difficult, as it is paved under the bottom of the body, where there are a lot of various aggregates and TC mechanisms.

Immediately add that the rubber sleeves make it possible to rotate.

With the components of the car suspension, the stabilizer is connected by amortized racks (so-called bones) and transverse double levers.

Moreover, such a compound is most often performed using the racks (in fact, the rack of the transverse stability stabilizer is a conventional traction), although it is allowed to produce fasteners and without the use of additional thrust.

Moreover, such a compound is most often performed using the racks (in fact, the rack of the transverse stability stabilizer is a conventional traction), although it is allowed to produce fasteners and without the use of additional thrust.

How do the front and rear transverse stability stabilizer work?

Design SPU is such that it is not able to counteract the angular longitudinal and vertical fluctuations of the car suspension. But with the alignment of the passenger vehicle in relation to the road plane and the rear, and the front stabilizer of transverse stability copes great.

The principle of their action is based on the verified redistribution between the components of the suspension of the loads entering the axis.

With angular oscillations in the transverse direction (with lateral roll), the car stabilizer is moving in different directions. As a result, one traction descends, and the second - rises. In this case, the bushings allow you to spin the middle part of the SPU.

The resistance of the described element increases with increasing the casual roll, due to which the car is aligned on the road. In addition, traction (bones) provide a higher quality of the clutch of the tires with a road surface when turning turns.

The transverse stability stabilizer of the rear suspension (either the front) performs its functions the better than the greater rigidity of its design. This indicator depends on:

- traction mounting geometry;

Forms of the mechanism and its conformity to "bending" the bottom;

The characteristics of the metal used for the manufacture of SPU.

A machine that has a hard front and rear stabilizer of transverse stability, it easily copes with the coolest rotations (and the driver does not even feel when they pass any roll).

And in front of the designers of cars, new opportunities are opening, because they can mount on the back and front axis of different stiffness of SPU. The installation of a transverse stability stabilizer of one or another stiffness allows you to achieve a certain balance of control of the vehicle.

Useful, but not always

To date, the transverse stability stabilizer is a mandatory part of the suspension of a passenger car, at the same time, its presence is undesirable in SUVs.

To date, the transverse stability stabilizer is a mandatory part of the suspension of a passenger car, at the same time, its presence is undesirable in SUVs.

An undesirable can be explained by the fact that the ability of the stabilizer reduces the movement of the suspension, and this is unacceptable when moving off-road, because the wheels are hanging out and lose contact with the surface of the road.

Of course, in the presence of a complete set of inter-axis and wheeled differentials, short-spectability will not be so dangerous, but in the absence of locks, the stabilizer significantly worsens the maintenance of the SUV. Despite this, it cannot be said that in modern high-speed SUVs a stabilizer in the suspension is an unnecessary detail.

On the contrary, for such cars with a high center of gravity, this item will be especially necessary.

From the operating conditions of the car, it is possible to make a choice than to sacrifice - permeability or stability. For example, the creators of Nissan Patrol Gr found output and applied in the suspension design of the electronic shut-off transverse stability stabilizer.

If you press the button on the off-road on the instrument panel, then the rod of the stabilizer cylinder, which performs the function of its rack, is released. The rod that moves freely does not transmit efforts from the sinks of the rear and left wheels, and when the speed is greater than 20 km / h, the control button the stabilizer is immediately blocked.

Thanks to such a reaction, it is possible to shut down the stabilizer error at high speed when dangerous rolls may appear.

The most actual transverse stability stabilizer was invented by the engineers of the American firm TRW. The design of this stabilizer provides a rack - a hydraulic cylinder, as well as hydraulic pump. These details "manages" an electronic control unit (ECU), which receives information from an accelerometer or lateral acceleration sensor.

The stabilizer is in unlocked state, when the car moves straightforwardly, the pump is in the off state, and the liquid in the hydraulic cylinder is not under pressure. At the same time, the suspension works in the most comfortable mode.

The stabilizer is in unlocked state, when the car moves straightforwardly, the pump is in the off state, and the liquid in the hydraulic cylinder is not under pressure. At the same time, the suspension works in the most comfortable mode.

When the lateral accelerations appear, the culprit of the rolls is an electronic control unit - includes a pump, and then fluid pressure is formed in the hydraulic cylinder. The electronic control unit, adjusting its value, changes, depending on the specific mode of movement, the stiffness of the stabilizer.

Let's summarize:the transverse stability stabilizer in the suspension design is the necessary part for traffic safety.

Advantages and disadvantages

With the explicit simplicity of the design of the mechanism of interest to us (only a reliable support is needed for its fastening, high-quality rubber sleeves, traction, bones) It easily copes with the tasks assigned to it.

But here it is worth saying that SPA reduces the course of independent suspension and "selects" some other important properties. For this reason, the installation of the transverse stability stabilizer is not carried out on off-road cars.

When driving on such all-terrestrial machines, equipped with off-road tires, the loss of the wheel with the road and its hanging is observed in poor roads. And such a negative phenomenon is determined by the use of SPU.

It is clear that autocontstructors are not going to abandon the use of the stabilizer and in these cases. Now there are several options for improving the design of SPUs intended for SUVs.

For example, TRW has created a modern system consisting of hydraulic cylinders who play the role of racks, a side acceleration sensor, a hydraulic pump and a special control unit. This system, which does not require rubber sleeves, has perfectly proven itself as an effective replacement of traditional SPU.

Also, Western automakers began to actively install adaptive suspension on their cars.These mechanisms provide an opportunity at all to abandon SPU, guaranteeing the perfect behavior of the vehicle (without rolls) in any driving conditions (when accelerating, turning, sharp braking, and so on).

Replacing and repair SPU

The repair of the stabilizer must be implemented in cases where its elements are explicit deformed. If you see that the rod flashed insignificantly, it is recommended to carefully align it. But with significant deformations, it is its immediate replacement.

In addition, repairs or replacement of SPU are manufactured with the loss of elasticity (strong worn out) of the mechanism of the mechanism, during their poor-quality adjacent to the rack. In order to repair or install new pillows, you need to perform the following steps: unscrew the fastening bolts from the bracket that holds the pillows; Slop the screwdriver under the bracket, carefully pinched it and remove it.

After that, you can remove the pillow (right to disassemble the cutting machine, left - to the center) and repair it or mount a new one. The removal and replacement of the poles also does not require too much time. The process of "on 14" keys is carried out by the following scheme:

- on the rod, unscrew the nut that holds the fastening bolt;

Get the sleeve (upper);

Move from the suspension lever The rack bolt (direction - down), after which two more sleeves dismantle - rubber and special spacer.

By the same principle, they are removed and the second rack, perform their replacement or repair, and then installed in the reverse order.

If you want to dismantle the bar, after removing the racks, it will be necessary to remove the pillows of the pillows (we have previously described this operation), after which the rod easily leaves the place of its placement.

Subscribe to our ribbons in