EGR in a diesel engine: what is it?

The EDR gas recirculation system (eng. Exhaust Gas Recirculation) is a solution to reduce the level of nitrogen oxides in gases that were used for gasoline or diesel engines. Given a system of hundreds of modern internal combustion engines daily only on gasoline.

For varying degrees, there are different standards for the toxicity of gases that were tested. Therefore, the EGR of a diesel engine can be implemented according to different schemes. The recirculation system for exhaust gas from the EDR of a diesel engine can be:

- high grip system;

- EDR low vice;

- combined EGR system;

What is the EGR system for?

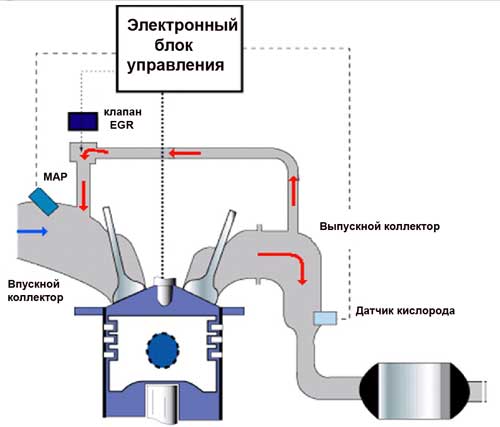

The main function of the EGR system is to frequently turn the exhaust gases back at the intake manifold of the engine for additional injection. The EDR of a diesel engine allows the robot to operate motors of a similar type soft and smooth, gasoline units with EGR suffer less from detonation. The gas recirculation system, which was tested, improved the performance of diesel or gasoline internal combustion engines, and reduced the amount of fire. Whiplash dviguna s EDR becomes less toxic.

The main task of the EGR system is to effectively reduce the level of nitrogen oxides in the fluff. The absorption of nitrogen oxides in the process of the robotic engine is caused by a high temperature. Raise the temperature in the combustion chamber to bring about an active increase in the amount of nitrogen oxides in the scorching sum. The temperature in the combustion chamber of the internal combustion engine is high, to the point that oxyfuel and nitrogen, as if they were in the air, that they were served, they began to interact with each other.

Povidrya sip in the combustion chamber of the combustion engine, de actively utvoryuyutsya nitric oxide. Tse means that the oxygen, which is necessary for the complete spitting of gasoline in units of this type, begins to be replaced by nitrogen oxides. Working together for the mind of the unsatisfied, the sour burns out in full obsyaz, the result is the exhaustion of the dvigun, the redness of the fire is noticeably moving, and the toxicity of the exhaust gases of the internal combustion engine increases.

By turning a part of the gas at the intake manifold, it allows you to slightly reduce the temperature of the combustion of the hot-smelling sum. Lowering the temperature automatically changes the rate of nitrogen oxide absorption.

The ingress of a part of the gas, which was injected, back at the inlet practically does not change the necessary spiving of the basic components for the removal of the fumes-powder sumishi, the engine itself does not suffer from exhaustion in different modes, and it also saves the burner.

Vimknennya EDR valve

In Europe and other developed countries, it is necessary to reach the nutritional ecology clearly. On the territory of the SND, there is an EDR that has an impersonal superechok. The topics of discussion among motorists are topics such as how to “muffle” the EDR of a diesel or gasoline engine, neutralize the gas recirculation system, what was done, turn on the EDR valve of a diesel engine, etc.

There are a lot of complaints that the recirculation system “suffocate” the motor and the EDR takes away the tightness, not allowing the engine cylinders to smell like a clean wind in the outside world. Before such one can see amateurs. No less common cause of recirculation is the intake manifold becoming more heavily polluted and the quick failure of the sensors in the system, as well as the EGR valve.

All elements of the recirculation system suffer from soot in the minds of the operation of the engine at a low temperature. Repair of the system will require a lot of financial investment. Deyakі vodiї z tsієї reasons negainno "jamming" the recirculation of gases, which they did, and do not allow for the validity of such a solution.

Recirculation of exhaust gases: EDR valve

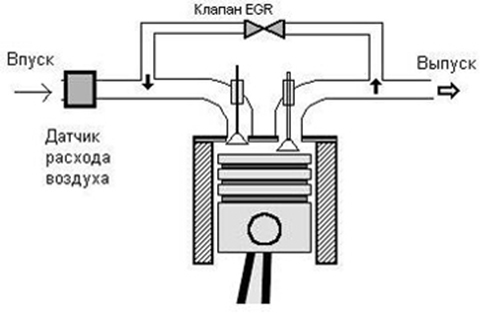

The head element of the gas recirculation system, which was worked out, is the EGR valve. The entire system is primed on the specified valve. The EGR valve itself is resolved, as it allows the first part of the injectable gases to be pulled back at the intake manifold, the stench was given anew to mix with the black portion again, which was at the intake.

The more sour is seen at the burning chamber, the more the temperature of the fire-hot sumishi comes out. Adding a part of the gas, which was taken, to the stock of the sum means a change in the amount of primus oil. Thus, a decrease in the temperature of the burning of the working chamber is achieved. The least quantity of sour means less intensive interaction with nitrogen, as a result, the quantity of nitrogen oxides in sourness decreases.

The EGR valve of a diesel engine or a gasoline engine is not the same, depending on the features of a particular type of diesel engine. The diesel engine has an EGR valve, which opens in the idle mode, between the intake of a fresh portion of the air. With more pressure on the EGR engine, less air is passed through at the inlet, and at the time of peak pressure, the valve will close more. This valve also closes in the diesel engine warm-up mode. What is the cost of gasoline internal combustion engines, the EGR valve closes at idle, and also for an hour the engine exits at the maximum moment to turn. If the pressure on the engine is low or medium, then the valve will protect up to 10% of the intake airflow.

Recirculation systems follow the principle of a closed circuit, and the EGR valve itself can be reversed:

- electrical controller;

- electropneumatic method;

For the first solution, the system spirals on data, which means that it is necessary to go from the position sensor to the internal combustion engine controller. The controller itself sends a signal to the valve. In another way, the regulation of the EDR valve operation is shown on the base, the reading of the pressure sensor at the intake manifold, the mass flow sensor and the temperature sensor at the intake.

The designs of the engines are being tightened, as if they may be on the way to reduce the cooling of the gases used in the process of the robotic recirculation system. The EGR valve in such designs is integrated into the engine cooling system. The system becomes more foldable, but the nitrogen oxide level changes even more efficiently.

For the first time, the system of recirculation of exhaust gases may have a number of advantages in the process of operation of the DVZ. For gasoline-powered engines, the advantages of the EDR are a smaller difference in pressure in the area of the throttle valve. The temperature of the burner has been lowered to change the detonation, allowing you to set the ignition of the momentary characteristic of the engine earlier. Diesel engine with EDR works softer and quieter in idling mode, small shards of acid reduce the pressure at the moment of ignition of the hot-swallow sumishi.

Types of recirculation systems for exhaust gases of a diesel engine

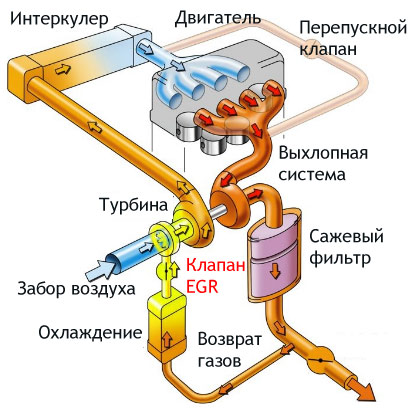

High pressure EGR is installed on diesel engines, as it is allowed to exceed Euro 4. High pressure recirculation system to frequently inject gases, which were inhaled, from the intake manifold of a turbodiesel, in front of the turbine. Then the system redirects the assigned gas to the channel, the smell of stench is taken from the intake manifold.

The system may have the same elements in its annex:

- recirculation valve with electric or pneumatic drive;

- branch pipes for the introduction of indpractic gases;

The recirculation valve (EGR valve) bypasses the intake of gases from the exhaust system to the intake. The pneumatic valve works to discharge the air that occurs at the intake manifold of gasoline diesel engines. For diesel units, a vacuum pump is also installed. Discharging, which flows into the recirculation valve, is regulated by the help of an electromagnetic vacuum valve.

The process of recirculation of inhaled gases becomes more and less intensive in the fallow in different modes in the robotic power unit. Stepin _intensivnosti without intermediary lie down in іd r_nіtі іskіv on inlet and outlet. The pressure at the intake system is regulated by an additional throttle valve. Closed throttle means that the vice on the intake is falling. At the same time, the recirculation of the gases in circulation is intense. Great recirculation to lead to a change in the flow of gases, which were injected, which directions to the turbocharger. To come out, at the moment of active recirculation of gases, which was practised, the pressure of the turbocharger of a diesel internal combustion engine fell, a kind of possession of an EDR of a similar type.

The EDR system is not active in idle mode, at the time of the throttle re-opening, and also during the engine warm-up hour and until the operating temperature is reached. Control over the operation of the recycling system is in place. The recirculation valve enters the robot with a signal from the electronic control unit of the internal combustion engine, which controls the position of the throttle valve with an additional potentiometric sensor.

Diesel DVZ, which comply with the Euro 5 standard, may have such a level in place of nitrogen oxide in the gases, which is not guilty of overestimating the indicator of 0.18 g / km. These engines work on a low pressure EGR system. The peculiarities of this system are those that the introduction of injecting gases into the soot filter of a diesel engine. Further gases are consumed from the radiator of the recirculation system for additional cooling. The next stage is the passage of gases through the recirculation valve and penetration at the inlet in front of the turbine.

The low pressure EDR system ensures the following:

- reduction in the number of soot particles;

- the temperature of the treated gases is effectively reduced;

- suttєve reduction in the amount of nitrogen oxides in exhaust gases;

An additional plus is those that gas, that it was pumped, pass through the turbocharger. This allows the recirculation system to operate efficiently without reducing the boost pressure. Come out, move the engine without straining.

The intensity of recirculation is implemented with the help of the engine ECU. Control is exercised for the help of such elements:

- throttle shutter;

- recirculation damper;

- exit shutter;

The shutters must be functional to ensure the visibility of the electric drive. Checking the shutters for one hour more value is measured by potentiometric sensors. Stupin rіvnya vіdkrittya zaslіnka ґruntuєtsya on a special program. The given digital circuit is hardwired into the ECU, the rotation of the cylinders of the engine, the indication of the pressure of the turbocharging and the levels of the intensity of the operation of the EDR system of a hundred different modes of operation of the internal combustion engine.

Diesel engines comply with the Euro 6 standard, but instead of nitrogen oxide in the windmill, it is not guilty to exceed 0.08 g / km, and a combined recirculation system is required. The features of such a system are two water-reinforced mains, which enable the recycling of distilled gases. One of the lines of the combined EGR system is a high pressure line, and the other is a low pressure line.

The system is combined pratsyuє similarly to the recirculation system on Euro 5 motors. The main task is to maximize the possibility of reducing the level of nitrogen oxides in grapes. Varto indicates that the radiator for cooling gases, which was worked out, in a combined system of a hundred and a half high-pressure mains.

The main causes of EDR malfunctions

The most common cause of malfunctions in the EGR system is soot. The sockets or the EDR valve plates are intensively dampened by soot. Nagar settles as a result of the operation of the DVZ on a low-capacity fire. The recirculation system also goes out of tune due to malfunctions and malfunctions in the robotic diesel engine living system, inconsistent combustion of the hot-spray sumishi, deterioration in the functioning of the crankcase ventilation system. The EGR system suffers from carbon deposits as a result of mechanical wear of the turbocharger, pistons and cylinders, coking of injector nozzles, as well as various malfunctions of the robotic sensors, which transmit signals to the ECU to control the EGR valve.

If the EGR valve is zasmіchivsya, vіn may be corrected incorrectly or jammed. In the first episode, there is an untimely valve response, which is noticeable in idling mode and there are no obvious symptoms and signs for DVZ. In another case, the EGR valve may be stuck at the moment of entry or closed. Gasoline units with a valve, which are jammed, the recirculation systems work at idle very unsteady, and the amount of fire is increased. Diesel engines with an inefficient EGR valve run tighter, rougher and louder.

In order to detect faults in the gas recirculation system, it is necessary to carry out a visual inspection of the pipe lines, electrical sockets, sensors and other systems. The diagnostics may be lost on the electronic scanning and a number of procedures for rechecking the functionality of the actuators of the same EGR valve.

It is necessary to reconsider the opir, as well as the presence of signals to control. For which vikoristovuetsya oscilloscope and multimeter. As a scan showed that the vice on the inlet is blown in the norm, and also the windage may be moved up again, even if the valve may be jammed. Replacing the EGR valve in parallel with the cleansing of the auxiliary mains and roses, shards of excess carbon deposits in the system can lead to repeated faults in the gas recirculation system after a small interval of an hour.