Designation of the engine cylinder.

Golovna

An engine cylinder block is a part of 2 or more cylinder piston engines.

The cylinder block has two main functions: it is a housing for housing all components, mechanisms and engine parts. Another thing is the cylinder block - the basis for the hanging parts of the engine: crankcase, .

Material of production of the cylinder block Chavun - Traditional material from which blocks were prepared until recently. Chavun is stagnated with additives: nickel, chromium. Positive components of the cylinder block: less sensitivity to overheating, harshness, required at a high level. The downside is that it has a big impact on the dynamics of a passenger car.

Aluminum - Sits in another place near the prepared cylinder blocks. Positive things

aluminum block: lightness

the best cooling.

As soon as there is a problem with the selection of material from which the cylinder can be formed.

U

- in our current minds

- , For the production of cylinders in aluminum engine cylinder blocks, the technology is developed: Locasil - pressed liners for aluminum - silicon, Nicasil - for the appearance of nickel coating on aluminum on the surface of the cylinder block.

- Low-power technology is of little importance to those who, if the piston burns out or the connecting rod is cut off, the nickel coating comes out of alignment and the cylinder block cannot be repaired.

The wine changes at the collection.

For replacement as a chavun, which is subject to a repair kit. Magnesium alloy cylinder block

- combines the hardness of chavun and the lightness of aluminum.

- A lest such a block, even if the road is satisfied, will not stagnate on the assembly line.

Leather materials have their own pros and cons, so it is incorrect to clearly state which one is better. Main benefits to the engine cylinder block

![]()

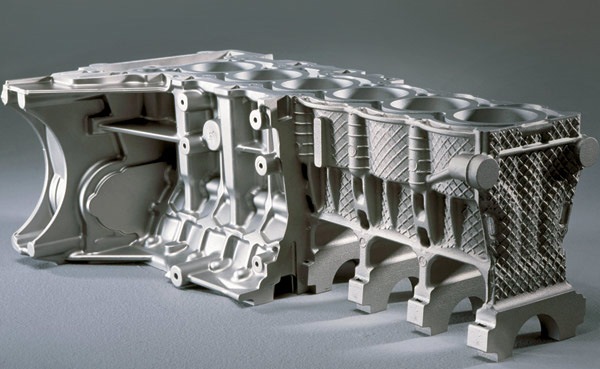

The cylinder block (engine block) is the main and basic part of the engine internal turmoil, this is where the main part of the equipment falls and where the main components and mechanisms are located. Therefore, the cylinder block is subject to severe stress, it is machined from high-yield materials and processed on special machines. Basically, the cylinder blocks are made from pearlite gray chavun with small additions of elements to lay them down, but the rest of them can often be molded with aluminum and infused with magnesium. The chavun mainly prepares blocks for vintage cars for tractor equipment, and for aluminum - for passenger cars and sports cars . On high-boost

sports engines With turbocharging, blocks from combined materials have recently begun to be assembled, internal part

Some of them are made of aluminum, and the outer one (where the cooling jacket is removed) is made of magnesium. Aluminum and combined blocks allow for a significant reduction in the power of the entire engine and the car as a whole, which is a great advantage for sports cars. For the folding structure of the labyrinth type with a large number of empty empty cylinders, the cylinder blocks are pushed under high vice. The highest vise allows you to take the correct shape, avoiding the creation of inhomogeneity and scratches in the “body” of the metal. Cylinder blocks, which are made from composite metal, are removed in a more folding way - first, the middle part is pulled out under a high vice using high-purity aluminum, and after that outer part with magnesium.

When preparing a cylinder block, ensure the installation method of cylinder liners (Figure No. 3). Cylinder liners are made from high grades of steel. Cylinder liners are either loose or cast in (mounted into the block); at present, cast in liners are most often used.

The poured sleeves are set in shape even before the cylinder block itself is created, which is injected together with the sleeves through the frame of which the diffusion of one metal into another occurs.

This method of preparing a cylinder block reduces the cost of manufacturing the internal combustion engine, and also reduces the maintainability of the engine as a whole. In the event of a breakdown due to natural wear or other factors, it is impossible to replace the sleeve and the unit is disposed of entirely. These cartridges can be either “wet” or “dry”.

The “wet” sleeve flows into the cooling medium, and the “dry” sleeve is inserted into the additional one. inner sleeve And does not stick together with the surroundings. Also, in aluminum engines of the first series there was a serious problem with the different technology of inserting the liner, so if the liner was poured in or installed “dry”, then after an hour the liner would split open the cylinder block for different parts linear kolivany at different temperatures. As a result, the advantage was given to “floating” “wet” sleeves. correct choice and preparation of bases to ensure the steel installation of parts for tools and working parts of the bench in all operations.

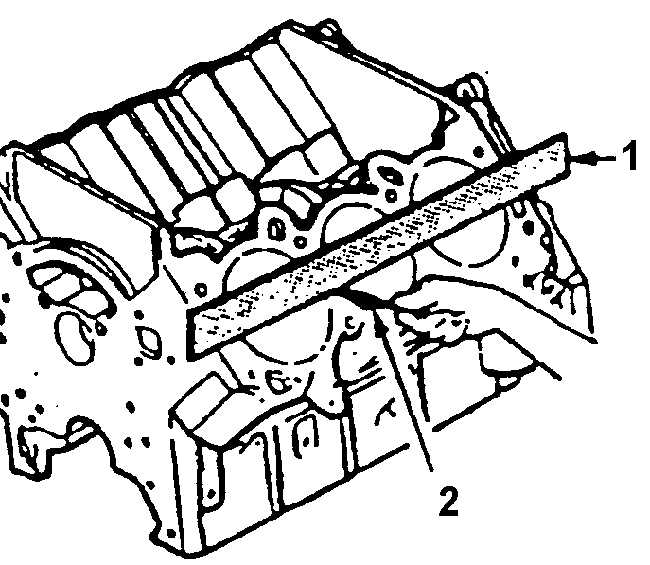

Most often, in the case of mounting bases when processing blocks, it is necessary to put together flat surfaces of great length and two openings, moved to the greatest extent.

For blocks, as a mounting base, you select the surface of the socket or the surface of the legs and openings for fastening, and as the core base, you select the openings for the cylinder liners and bearing housings.

The sockets for installing the main bearing covers should be trimmed with a set of cutters with a sub-cut assembled broach on special broaching workbenches and basic horizontal broaching workbenches, equipped with devices for fastening the part and broaching line.

The end surfaces of the great blocks are laid out on horizontal scouring benches.

The surfaces of the cylinder heads (heads) of the blocks of large engines, especially at the drops, when the surfaces of the parts have protrusions and grooves, are measured on carousel benches.

The surfaces of small blocks are trimmed on late-grinding broaching benches.

The machining of the main openings is carried out on universal horizontal boring and radial drilling workbenches according to the layout. The grinding of blind openings is carried out using boring bars, mounted in a cantilever manner in the spindle of the bench. internal combustion of the cylinder block.

The engine cylinder block is installed on a diesel engine with 2 or more cylinders.

The cylinder block is formed into one solid cast part, which is intended for the following functions: connecting all the engine cylinders, as the basis for the hanging parts (cylinder head, crankcase) and in the middle of the design parts for the crankshaft, channels for coating and cooling systems.

- The cylinder block has two main functions: it is a housing for housing all components, mechanisms and engine parts. Why is a cylinder block prepared? The most extensive material used in the production of the engine cylinder block is chavun. This is traditional material.

- Material of production of the cylinder block Let's look at the list of aluminum types and different alloys.

- The most acidic material for the cylinder block is magnesium alloy. It has such positive characteristics as harshness and low sensitivity to engine overheating.

Cylinder block, devices that work in permanent change

- temperature conditions That's why the chavun bloc is leading here. With this, there is a great minus of the chavun block, the mass is great. There is such a positive power, as the engine cools down and the mass is small.

- The peculiarities of aluminum blocks include the selection and installation of sleeves. The most advanced technology today is Locasil - pressing of sleeves with aluminum - silicon and Nicasil - nickel coating.

- Lack of other technology - it is not repairable. The cylinder block of low-power technology does not undergo refining, but is changed during assembly. This is not suitable for the owner of the car. Magnesium alloy

- does not stand up for conveyor production of the cylinder block through its road. I want the ideal combination of hardness and value of chavun and lightness of aluminum.

Main storage cylinder blocks

So this is where all the most important components and engine units are located.

This detail itself receives most of the attention (up to 50 thousand).

Therefore, the cylinder block (VAZ 2114 among them) must be prepared from the highest grade and wear-resistant steel on special high-precision machines.

Functions

This mechanism has many functions: it serves as the basis for the hanging parts of the engine (cylinder head, crankcase, etc.), and also serves as a housing housing all engine parts. Material Big part

current cars equipped with single cylinder blocks. Chavun is diluted with nickel and chromium additives, which is why it becomes soft and wear-resistant.

The main passes of the given mother є ogi, to overheating, that zhorstki, Yaka Potribna for the leap step is the short -term chalk of the chavun unit of the oga Vaga Vaga, for the rachonki, the dinamobil dinamobil.

In order to rev the car to the required speed, the engine has to rev up more force, and therefore, the traction of the movement Ale, as a rule, the car spends no more than 1-2 hundred kilometers per hour and burnt fire.

- Aluminum is a less popular material for the production of these viruses.

- Let's paint the butt of the frozen aluminum blocks and the made Gazelle and the Zhiguli model.

The main advantages of this material lie in its light vase

more beautiful than power refrigeration However, now car enthusiasts identify a problem with the lack of necessary material from which the cylinder is made.

The crankcase is the main part of such a part as the cylinder block.