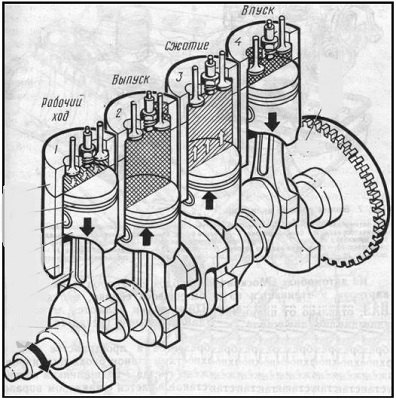

The appointment of that power of the bell-shaped shaft - in clear words about the details. Kolinchastiy shaft dviguna

The crankshaft, through the connecting rod, receives the pressure of gases, which is driven into the over-piston empty cylinders, and is navantazhuetsya by the forces of inertia in the neuron-invading mass mechanism, which induces a reversible forward and overt rotation. Under pressure, they change sharply due to the magnitude and direct gas forces and forces of inertia, the shaft is wrapped around with a changeable apex screw, after which there is spring colivannya, twisting, bending, or tightening.

Folding smart robotic shaft shouting advance payment yogo shiyok, the deformation of the okremikh elements of the design and the phenomena in the material, generate torsion and axis of the yogo colivanna. The construction of the bell-chassis shaft is due to the mother's sufficient strength, hardness and wear resistance with a similarly small vase.

A striking view of that structural element of a typical shaft of an automobile piston engine is shown in fig. 1, a b. Kolіnchasti shaft dvigunіv avtomobilі and tractor types are prepared by the method of forging or casting from medium carbon steel grades 45, 45A, 45G2, 50G; alloyed steels 45ХН, 40ХНМА, 18ХНВА or high-yield chavunіv (magnesium, nickel-molybdenum, etc.), which may increase the mineralization.

Rice. 1. A striking view of the structural elements of the crankshaft of the V-like 8-cylinder engine ZIL-130:

I, II, III, IV - crankpins

The main elements of the crankshafts are: root and connecting rod necks, pins, shank and cap. Before the obov'yaskovyh elements of such structures of automobiles and other similar shafts, there are also counteragogues. Filed in fig. 1 motor shaft ZIL-130 and in this way is typical.

Root necks 12 serve as shaft supports, on such veins they are laid and wrapped around the main support (root) bearings of the engine.

Connecting rod pins 11 serve as a swivel joint to the shaft with the lower heads of the connecting rods. Connecting rod pins and connecting rod heads installed on them are called different cranks. Oliya goes to them for drills 5 types of shiyok 12.

Joints 13 are combined into one joint of the connecting rod and the root neck. Two pins, which adjoin to the summіzhnyh root necks at once with one or the other dekilkom connecting rod pins, fix the crank-thorns (knees) of the shaft.

The shank is called the rear part 6 of the shaft, as in automobile engines it ends with a flange 7, secured with openings 4 for fastening the flywheel. At the end of the shank, a socket is drilled 8, the support bearing of the primary shaft of the gear change box, and on the cylindrical surface, there is an oil-drip bead 10 and an oil-drip groove (spiral groove) 9 or a smooth neck of the oil seal.

The toe is called the front part of the 14th shaft, on which they are installed: the gear for the drive of the gas vent, the oil pump and the fan pulley, and in the threaded opening 15 from the end - a ratchet, which is necessary for turning the crankshaft when starting the engine manually. If the manual start is not transferred, then a bolt is installed instead of the ratchet, which ensures only fastening of parts on the bearing shaft. At the groove 16, a key is laid, which fixes in a strictly specified position the gear to the drive of the gas vent and reduces the rotation on the wear and other details.

The counterweights 1 are installed on the cheeks 13 from the side, protilezhnoy crank, and serve in the multi-turn engines for total or partial separation of the root supports in the form of the main wind-center forces. In a number of moods, stench is necessary for the recovery of motors.

Kolіnchaє valі bugatotsilindrovyh dvigunіv є foldable spacious design, the shape of which is rich in what is determined by the number of root supports, accepted for this dvigun. At this link, the kolіnchastі vali podіlyayut on povnoopornі and nepovnoopornі.

Rice. 2. Non-supporting crankshaft of an in-line 6-cylinder GAS engine:

1 - flywheel mounting flange; 2 - counterweights: 3 - root necks; 4 - connecting rod necks; 5 - toe shaft

At full-bearing shafts between two summed root bearings, only one connecting rod neck is placed, so the number of root bearings is one more than the number of connecting rod bearings (div. Fig. 1). So, you can stop at diesels, carburetor V-likes and other engines that work with great vanity on bearings.

Non-supporting kolіnchasti rolled on two and more connecting rod journals between two summіzhny root supports. The stench is more compact (shorter) than fully supported, sometimes it is easier than them and less laborious. Ale, through a span of a great span between the root supports, such kolіnchasti fell not enough hardness. For non-supporting automobile shafts, the typical design of the shaft of the GAZ-51 in-line six-cylinder engine is shown in fig. 2. Massive counterattacks serve here as a rallying of the root supports of the maternal air-center forces.

Columns of automobile and tractor engines are subject to static and dynamic balancing in assembly with a flywheel and a friction clutch. Without this important and practical concern, it is impossible to secure a calm movement of the engine through yoga promotion of vibration.

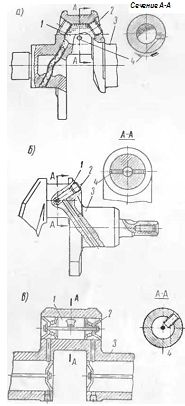

Rice. 3. Crankshafts of the crankshafts:

a) cast shaft of the ZMZ-21 engine; b) forged shaft of the MZMA-408 engine; c) forged shaft of V-2 engine; 1 - mud trap; 2 - plug; 3 - main journal: 4 - channels for bringing oil to the surface of the connecting rod journal

For the zbilshennya Znosostіykostiyoku, the valus of the superficial curtains of the chimic frequency for a glybin of 3-5 mm to the hard-resistant HRC 50-60 ry is in the way not guilty of overshooting 0.01 mm). The thickness of the hardened ball is selected based on the correction of the change in the diameter of the necks in the course of regrinding during repairs of the engine.

Shanks of the shaft with the method of changing the yogo vag are often empty, which is easily reached when the shafts are pulled in.

On fig. 3 indications of one of the cranks of the cast shaft of the ZMZ-21 engine, in which case the forks are held in the necks when empty.

At this point, oil is supplied from the roots to the connecting rod necks for additional tubes, which are pressed into the opening, drilled through the walls of the empty root necks. To fix the tubules in the required position, they are slightly bent, as shown in fig. 3 a. Empty 1 in the connecting rod necks, closed on both sides with threaded plugs, mud traps. However, open 4 to supply the ole to the connecting rod bearings with such a spliced neck, the empty bearing is drilled on the equal axis of the neck, or trochi below it and perpendicular to the plane of the crank (div. Fig. 3, a). The same important particles in oil, including wear products, which are thrown by the center force to the greatest distance from the axis of the wrapping of the walls of the empty, are not consumed by the connecting rod bearings (the scheme for catching such an accumulation of important particles is shown in Fig. 3, a).

Dodatkove vodtsentrove purifying oil in the dirt traps of the connecting rod pins of a wide-width nabula. The connecting rods of the necks of forged shafts are specially hardened using a method. Otrimani in such a rank dirt traps are depicted in fig. 1, a, b and fig. 3, b, b de shows the cranks carburetor engines V-like ZIL-130, in-line MZMA-408 and V-like V-2 diesel engine. At the rest, the oil is brought to the bearing of the head connecting rod through the middle tube 4, which is zanurenny with a pick-up tip without a middle into the mud trapping empty. Two connecting rods are placed on the leather connecting rod neck of the ZIL-130 engine, including the empty dirt-trapping rods 3, which are closed with threaded plugs 2 (div. Fig. 1, a), visverdlen here from two sides of the crank. With the presence of one connecting rod on the neck, one empty rod is sufficient, which is visible behind the diagram of fig. 3b.

Rozmіri (diameter and dozhina) of the neck of the shaft is selected from the improvement of the earlier constructions, and then they are specified with the correct rosette. The connecting rods of the necks at the skin shaft, as a rule, may have the same expansion, and the roots often tear their dove. The largest shaft is sounded by the extreme necks, especially the back neck, which adjoins to the shaft shank, which carries additional pressure on the flywheel and the clutch. So, the back neck of the ZIL-130 crankshaft should be 45 mm versus 31 mm for the other main journals, and the ZMZ-66 engine all the main necks of the ZIL-130 should be the same. This allows you to install interchangeable bushings for all of your main bearings, which is more cost-effective.

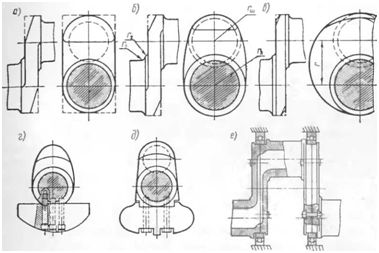

Rice. 4. The design of the crankshaft shaft and the fastening to them is opposed.

In a row with the extreme necks in a row of structures, the middle root bearings should be supported, as it is necessary for the minds of the assembly of the engine, and in general, the main root necks of the shaft should be changed. The shorter the neck and the smaller the shaft shaft, the greater the hardness of the shirred construction. The hardness of the shaft moves behind the rahunok “overlapping” the shiyok. It is especially pronounced in today's short-range automobile engines, in which the sum of radii r to + r w of the main and connecting rod bearings is greater than the radius g of the crank (div. Fig. 4, b).

For the promotion of the deep scarcity of the shaft, a pair of ribs with necks are wound with smooth transitions (div. Fig. 4, b) - zholobnikov. It is recommended to choose the radii of the collars in the range of 0.06 ÷ 0.1 according to the diameter of the necks. Zavdyaks to fillets noticeably change mistsevі naprugi in the zone of obtaining cheeks with necks. And if so, the ribbed grommets change the active neckline (the cylindric part, which is located under the inserts), then the whole grommets work with the lower ones: from the neck to the technological belt with a radius of r 1 (the main part of the radial transition) and farther to the th r 2, as shown in fig. 4b.

A small technological belt near the zone where the collar is made from the necks and the shaft is a structural element. When working with a shaft of wines, it protects the grinding wheel from a possible unsafe shock.

Give the cheeks an oval, round or prismatic (rectangular) form. Prismatic cheeks are the most simple, but behind the minds of the mind, the stink of the stench comes out in pairs, so that it’s easy to re-arrange the shaft and increase its dimensions. AT car engines old models, where they knew they were stuck with prismatic cheeks, the rest were stuck with rounded edges of the tacos (div. Fig. 4, a). Tse allowed to lower the head shaft. It should be noted that, with the method of changing the shaft, the parts of the cheeks are of little interest (the edges on the side of the protilezhny shaft obtained from the necks) in case of any of their forms, as shown in fig. 4, a-e.

Round cheeks (div. fig. 4, c) are handy for mechanical processing and may have sufficient strength with a remarkably small torso. The crankshaft of a V-like 12-cylinder V-2 diesel engine is prepared with round shocks. Round shackles can be twisted as well as root bearings in dviguns, the shaft of which is wrapped around on the stiffness bearings. In these cases, it is most common to have a choice of shafts, which are provided with bag or roller bearings. Structural elements of the crank shaft roller bearings shown in fig. 4, e.

Oval cheeks (div. fig. 4, b) for their mіtsnіstyu little do not give in to round cheeks, but with such a form, it is better to vicorate metal and ensure smooth transitions between okremi elements shaft structure (div. Fig. 4, b). Zavdyaki oval schoky widely zastosovuyutsya in automobile and tractor swedkohіdnyh dviguny.

In the fallow, the shaft is divided into short and long spans. Long and short ribs are fixed for non-flush bearing shafts, and in in-line 6-cylinder engines, long ribs are bent (div. Fig. 2). Chocks of the wheel shafts of automobile and tractor engines are often driven or driven together with counters (div. Fig. 1 and 2).

Countervails, vykonanі okremo vіd schіk, krіplyat to them on studs or bolts, as shown in fig. 4, d, e. The stud nuts and bolts are effectively blocked due to possible weakening of the tightening. Some people swear by electric cooking. The thickness of the counterweight should be chosen so that when repairing the engine, the rest did not complicate the regrinding of the shaft.

Like the bearings of the main bearings in automobile engines, they sound like thin-walled bi-metal or trim-metal liners.

Design, technology of preparation and fixation in supports of similar design with bushings of connecting rod bearings. In the rest of the stench, they are only blown with a large steel line, for which they are stamped. The deep look of the liners of the root bearings (bearings) is shown in fig. 12 (position 12). For most industrial automobile engines, insert liners of main bearings from a steel joint of 2.25 mm. Car engines GAZ-53A, GAZ-66 and ZIL-130 are equipped with trim-metal liners of main bearings.

Kolіnchasti shafted suvoro fix in the axial displacement in the root bearings, as in automobile engines it is allowed in the boundaries of a total of 0.2 mm. Due to the greater size of the displacement, the problem of non-baggage damage due to freezing of the parts of the crank mechanism is blamed. As a rule, the axle fixation is installed only in one of the root supports in order to save the possibility of moving both the shaft itself and the elements of the skeleton of the engine during thermal expansion. To fix the vicorist, use either extreme supports (rear - for the YaMZ-236 engine; at the toe of the shaft - for all engines ZMZ that ZIL-130), or the middle support (dvigun MZMA-408). With a helical gear or lance drive of the camshaft gas-spreading for fixing the shaft, it is recommended to twist the front main bearing.

Columns of automobile and tractor engines at the exit from the crankcase are guilty of deepening at the nests. With an insufficiently strengthened shank and wearing a shaft, it is possible as a winding of an olії z poddon, so it is possible for a road saw to penetrate into the crankcase of an empty engine. The flow of oil does not only increase the heat, but it can also cause an accident through a "badass" or melting of the bearings due to overheating. Not less unsafe and penetration of the road saw, which causes the wear of parts of the crank mechanism.

The kolіnchasti shaft is strengthened for the help of small oil seals, as well as oil and sawmill outbuildings. The strengthening of the scarf shaft is especially foldable.

From the outer side, open at the krishtsi, through the yak to pass the scarf to the shaft, protected by stamping with a saw blade, pressed onto the hub and wrapped at once with a fan drive pulley. Pilovidbivach pereskodzhaє penetration to the stuffing box and into the crankcase of the road saw.

The design of the crankshaft and its shape are chosen in such a way that, regardless of the tactality of the engine, it would be safe to draw the working strokes even if the accepted number and expansion of the cylinders were reached, and it would also reach a larger outside of the engine.

Z tsієyu method kolіna va-la, rivnovіddalenі vіd yogo middle (vіd аsі symmetry), roztashovuyut in one plane. In chotiritactic single-row engines, the qi of the column are turned in one beat, so that it can be mirrored.

The numbering of working moves at the cylinders is called the order of the robotic engine. For the accepted mutual frosting of the connecting rod pins to the shaft, or kuta zsuva of the first column, it is necessary to establish a sprat of order, and to beat that one of them, which will ensure a greater equal distribution of the tension along the shaft. Sequentially, the working cylinders of the engine are due to one type of one yaknaidal.

Kolіnchasti shafts of piston dvigunіv vіdchuvayut zmіnnі twisting navantazhennya, under the infusion of which they blame the spring kutovі kolyvannya. The essence of such colivans can be understood on the butt of some kind of spring shearing, which is firmly fastened from one side and carries weight to the other. If you twist the twisted wave of the looked-out shear on a deaky kut and let it in, then under the force of springiness and the inertial mass of the wines, you will create a cut-off with a singing frequency (period). Varto only to such a haircut that it is splintering, apply a strong force, periodically blowing with the same frequency, as a result of a resonance (rhythmically breaking), which calls out without interruption the increase in the amplitude of the sharp cutting of the haircut and in the end result of the collapse.

Similarly to this, the kolіnchasti shaft, to the crooked spikes of which zvnіshnі forces are applied, which blow periodically with the frequency, which lie in the number of shaft wraps, the cycle rate of the engine and the number of cylinders. When zbіgu period on the shaft, be it a harmonious warehouse of forces from the period of yogo coliving, it is a manifestation of resonance.

The number of revolutions, which indicates the blame for resonant colivans, is called critical.

During the design of the crankshaft, it should be changed to the extent that it is more critical for the new number of revolutions, which gives the most unsafe resonance, it is not enough that the greater value of i did not fall into the range of the working numbers of revolutions of the crankshaft. With this method, the shafts can be given more hardness. From the theory of coliving, it is clear that the greater the hardness of the shaft at given moments of inertia mass, which are cobbled together with the shaft, the frequency of the wet colivans to the shaft of this system is higher, and the number of revolutions is more critical. As a result, in the range of working numbers of revolutions of the shaft, harmonies of higher orders of magnitude resonate. Since the amplitudes of these harmonics change with the advancement of their order approximately exponentially, then the resonance of these harmonics is not safe for the shaft, the higher the order of the harmonic.

If, when the shaft is turned on the torsional colivan, the resonance of the harmony is of some order, which occurs in the working zone of the numbers of revolutions of the shaft, to appear unsafe for the shaft’s strength, then the dynamic system is changed by changing the hardness of the shaft. As constructively valuable, it is necessary to put a quencher on the chimney, on the quencher of the chimney of a given form, which is distinguished by its frequency.

The principle of dії oscillators of torsion coliving foundations on private clay energy (which is the cause of the torsion colivanna of the crankshaft), which is rubbed on the robot by rubbing into the quencher. Extinguishers are installed on the nose shaft, or in a non-intermediate proximity, de kutovі mаyut maximum value.

In car engines, dampers of friction (dry grating), internal grating (humic) and common grating are installed. The most simple and widest dampeners for internal friction are dampers (Fig. 5).

Rice. 5. Torsional damper for the internal friction of the engine ZIL-114

A massive disk (handwheel) 1 is vulcanized here with a gum ball 2 to a stamped shaped flange 3, which is hard to fasten to the mother of the fan drive pulley. Twisting knurling of the crankshaft calls for the knurling wheel of the handwheel 1 but the shaft. After all, in the balls of gumi, the internal rubbing, which dries part of the energy of the torsion coliving shaft. Tsya energy is transformed into heat and diffuses into the atmosphere. The gum dampers change the amplitude of the hull knocks on the dvigun shaft, which absorbs the change in voltage, which is blamed on the new one. The stench is effective, it's easy for the outhouse and it's better to work.

In the given hour, extinguishers of the native tert, in such vicorous silicon native land, which have great viscosity and little to lie in the temperature. At the closures, the expanse of the silicone damper is placed in a seismic mass at the sight of the ring, and a silicone motherland is poured into the empty void, in which the seismic mass is to blame. Rubbing, scho vinikaє mіzh vіzkoy rіdina and tsієyu ruhomoy masa, vykoristovuєtsya for quenching (weakening) torsion kolivan shaft.

The need to install dampers for the crankshafts is due to in-line 6 and especially 8-cylinder engines, which may be equal to the large shaft shaft.

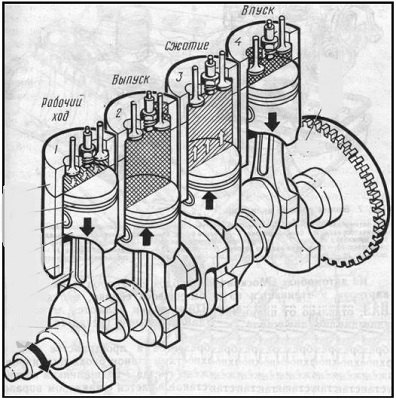

The crankshaft is located in the block of the engine cylinders and allows you to convert the reciprocating rotation of the pistons with the connecting rods into a wrapper. This wrapper is transmitted through the transmission to the wire wheels of the car.

A ring is being prepared for forgings from high-alloyed steel, or a forging from high-quality chavun, with advance grinding and mechanical processing. Shards of the moment of the wines are not hot, then they are powerful to the point where the twist of the bell-shaped shaft is higher than the temple.

Yak vlashtovan crankshaft

Kolіnchastiy shaft, tse crank. Zvіdsi i name "crank-rod mechanism". Until the new part of the shaft enter at once with pistons, rings, pins and connecting rods. And also a flywheel with a crown and a pulley to drive additional mechanisms.

Name it clearly, the shaft is not straight, but may be such structural elements as a column. The stench is called connecting rod necks.

- In row motors, their number is more expensive, the number of cylinders - a leather piston with a connecting rod is poured onto its neck.

- V-like i boxer engines, one connecting rod neck can be recognized for spriynyattya navantage in the presence of two connecting rods and pistons from the sudo dnіh rows of cylinders.

The center of the wrap around the crankshaft is the root of the neck. Between the roots and the connecting rod necks there are cheeks, on some vikonan elements, like they are called counterags. The transition from the skin neck to the cheek of the chicory is not under a straight cut, but the radius is a groove. The fillet is needed to prevent the appearance of small cracks, since in this region the greatest concentration of stress was on the metal.

- The main necks are larger in diameter, lower connecting rods. Connecting rod necks are drawn from the roots and the number of remaining larger crankshafts.

- Kolіnchasti fell, yakі do not wash the root necks from both sides of the connecting rod - not fully supported, the rest of the hour may not be stuck. It was tied to the zі zbіlshennyam vymog to the hardness of the kolіnvalіv through the growth of the squeezing of the modern dvigunіv.

Like bearings in which the necks of the crankshaft are wrapped, the liners are vicorous. Inserts forged bearings. The stench is made from steel smuga, bent along the radius of the neck of the crankshaft and covered with a thin ball of aluminum alloy, or bronze, which has a low coefficient of friction. There are locks on the inserts, which help them to turn pastels.

Between the neck of the crankshaft and the surface of the liner, the clearance is transferred. When the engine is working, in this gap there is always an oil spit - an oil wedge. Vlasne, the main shaft is wrapped around the same oil wedge, but not on the bushing.

For bringing the oil to the contact of the necks and bushings, in the crankshaft - oil channels, connected to the main oil line and the oil pump.

For motorcycle two-stroke engines, as well as industrial and strong diesel engines with a large working volume of cylinders, such bearings for crankshafts can be stuck:

- kulkov_ bearings of stiffness;

- rolling roller bearings;

- head part bearings of stiffness.

To transfer the moment to turn, a flywheel is bolted to the transmission, on the rear end of the crankshaft. For the sake of their great vag and inertia, vin smoothing the pistons and pistons during their working progress.

In the rest of the hour, the double-mass flywheels are expanding, which plays the role of a damper for torsion coliving.

For transmissions mechanical boxes gears, flywheel є conductive disk zcheplennya. For transmissions automatic boxes gears on the flywheel, the body of the impeller of the hydrotransformer is attached.

On the front end of the crankshaft, as a rule, on the keyed drive, a gear is mounted - the gears of the pulleys for the timing drive and the pulleys for the drive of auxiliary mechanisms.

Through the light trend of motor production to change the shaft and the expansion of the details of the crank mechanism, as well as the increase in nominal revolutions and the stage of compression of the engines, the problem of resonant knockouts appeared, which lead to breakage of the crankshafts. For її usunennya, dampers began to be installed at the pulleys of the crankshafts to dampen the torsional vibration. How it was planned, which one is intended for dual-mass flywheels.

Incorrect crankshaft

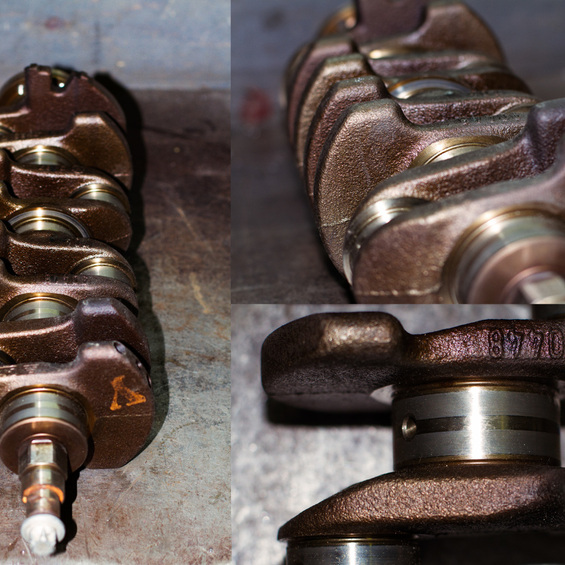

To the main faults of the kolіnchasti shafts can be seen:

- znoshuvannya shyok, їх fusion with antifriction coatings of liners;

- cracks in the necks;

- wigin crankshaft;

- cheek breakage.

The widest injustice is the depreciation of shiyok. The sign of the boundary wear of the crankpins of the crankshaft and their inserts, є metal knock, the frequency of which is doubled less than the frequency of the crankshaft wrap. After the engine has warmed up and under pressure, the knocking will increase. As soon as you turn on the nozzle, otherwise the supply of voltage to the spark plug in the cylinder, the connecting rod of such a mutually worn neck, the knock will change significantly, otherwise it will disappear.

A deaf metal rattle, which is more frequent than the wrapping of the bell-shaped shaft, which will increase under pressure and after the engine is warmed up, it is a sign of emergency wear of the root bearings and their bearings. Such a knock can also be said about the deformation of the crankshaft through overheating of the pins when the bushings are ruined.

Decrease the pressure of the oil system, especially on idling of a warmed-up engine, and a knock after the start of the engine, which quickly disappears, also as indirect signs of wear of the bearings and collars of the crankshaft. In case of breakage of the crankshaft, I charged the main neck, so there will be a slightly metal knock, a multiple of the shaft revolutions.

Cracks on the necks show up on the crankshaft taken from the engine.

Traces of vikoristannya wrong kolіnvalu

If you continue to operate the engine with obvious signs of severe wear of the crankshaft, then the consequences of such operation may be:

- view of the oil wedge in a pair of insert-neck;

- dry rubbing;

- overheating and fusion of the neck with aluminum coatings of the liners and further jamming of the crankshaft.

If everything is running at high speeds, then turning the inserts on your pastels, with a distant expensive repair of these pastels, or replacing the cylinder block and connecting rods, is also possible.

As a result of the operation of the engine, the crankshaft of some kind of cracks, as well as the breakage and deformation of the pastel inserts in the block.

After the jamming of the dvigun, having caught it, it is not necessary to try to turn the shaft of the great komir, or from a tugboat. The last thing on the shoes will be the turn of the liners, which are welded to the collars of the KV, in pastels.

How to correctly install the crankshaft

In case of independent “stacking” of the crankshaft into the engine of your car, you need to remember the simple rules:

- between the surfaces of the collars of the crankshaft and the liners of the shoes, there must be a gap for the oil wedge. The value of this gap is set by the dialer of a particular engine. The gap is not to blame for qi tolerances;

- crankshaft, yogo channels, cylinder block, liners and hands of the choice of guilt must be perfectly clean;

- the diameter of the crankshaft pins is due to the factory tolerances of the dimensions of the bushings. It is not possible to seal the inserts of repair expansions and navpak with the necks of the nominal size. With the number of nominal rozmіru vikoristovuvat more than nominal tabs. If the necks of the crankshaft are polished and repaired, then the inserts need to be repaired.

- before laying the crankshaft into the cylinder block, it is necessary to re-convert both the connecting rod bushings and the connecting rods themselves. Just before repair, I’ll have the connecting rods welded, or the bushings turned, it’s necessary to tighten the connecting rod cap with a torque, proponated with a screw, and check the inner diameter of the lower connecting rod head to fit the factory dimensions. In times of inconsistency, replace the connecting rod.

Everything is fine with the connecting rod, you need to insert inserts into the connecting rods, cover them with oil, rather transmission, and tighten with a moment. Leather on his connecting rod neck. Having turned the connecting rod on a sprat of wrappers around the neck, we know that it is overturned on the surface of the liners. They are not to blame for the occasional traces of contact from the connecting rod. Yakscho є follow the torsional, and the connecting rod is importantly checked on the side, the tab can be replaced.

It is necessary to remember that the cover at the factory was sharpened at once with its connecting rod, at the position, if the grooves under the locks of the liners are located on one side. That is why it is not possible to stray between yourself and that connecting rod. When installing the cap on the connecting rod, the locks of the hinged inserts are located on one side.

Having checked the connecting rods and their bushings, proceed to laying the crankshaft in the cylinder block. Mostly up to pastel, the core inserts of the cylinder blocks are the same as those of the connecting rods. In addition, the pastels in the blocks of cylinders are made of hardwood pine. Nonspіvvіsnіstyu and wear pastelіv especially skhilnі cylinder blocks from light alloys.

Even with the expansions and the spiving of pastels, everything is in order, we insert inserts into them. As a rule, the main bearings, which are inserted at the block of cylinders, make a groove in the middle for a shorter oil change, and the bearings in the caps, on the basis of which the main pressure is placed on the hour of the robotic engine, are strong. It is impossible to stray when folded.

Having installed the kiltsya at your pastels, we put oil on them and put a shaft in them. We install the caps of the main bearings in their place and tighten them with a proper moment. The puff is started from the middle cap to the extreme ones, in the check order.

The caps cannot be strayed among themselves, for that, open the crankshaft at the block of cylinders, they will grow in one pass, from the tightened bolts, the caps are fastened. With this groove, the locks of the inserts at the pastel block of cylinders and the її krishtsі are located on one side. In such a position, it is necessary to install when selecting a crankshaft with a block.

After tightening all the caps, check the crankshaft for a sprat of wrappers. Vіn is guilty freely, without zaїdannya provertatisya in the hands. Zamіryaєmo axial clearance between napoleglivnymi pіvkіltsyami and shkokoyu and znіmaєmo kolіnval.

Let's look at all the tabs. It’s not their fault buti slidiv torkannya shiyok. If so, and reducing the axial clearance, the axial gap is closed to the norms, the remaining part of the shaft is placed in the cylinder block and the caps are tightened in the central section to the extreme moment.

As if the bushings are pressed, and with the geometry of the crankshaft and pastels in the cylinder block, everything is in order, so the bushings can be replaced.

Axis of water and everything about the shaft shaft.

› Crank mechanismKShM takes the pressure of gases during the working stroke and transforms the reciprocating motion of the piston at the crankshaft crankshaft. KShM is composed of a block of cylinders with a head, pistons with rings, piston pins, connecting rods, a crankshaft, a flywheel and a crankcase.

The block of cylinders is the main part of the engine, to which all mechanisms and parts are attached. Cylinder blocks are made from chavun or aluminum alloy. At the same time, the fork of the vikonan crankcase and the walls of the shirt are cooled, so that the cylinders of the dvigun can be felt. Insert sleeves are installed at the cylinder block. The sleeves are “wet” (cooled by the motherland) and “dry”. Sleeveless blocks are installed on modern engines. The inner surface of the sleeve (cylinder) serves as a direct line for the pistons.

The block of cylinders to the beast closes with one or two (for V-pro different engines) cylinder heads made of aluminum alloy. At the head of the cylinder block (cylinder head) there are combustion chambers, for those with threads open for ignition candles (in diesel engines - for ignition candles). For DVZ heads with non-intermediate thrusts, there is also an opening for injectors. For cooling the chambers burning around them, a special shirt was worn. On the heads of the cylinders, the details of the gas-flow mechanism are fixed. The cylinder head has inlet and outlet ducts and installed insert seats and straight valve bushings. For tightness between the block and the cylinder head, a gasket is installed, and the heads are fastened to the cylinder block with studs and nuts. The head of the cylinders is closed with a cap. An oil seal is installed between them.

The piston takes pressure of gases during the working stroke and transfers it through the piston pin and connecting rod to the crankshaft. The piston is an inverted cylindrical bottle, made of aluminum alloy. At the upper part of the piston, the head with grooves is ruffled, and piston rings are inserted at the yak. Below the head of the vikonan is the back, which directs the piston movement. At the back of the piston there is a bobby pin with openings for the piston pin.

When the engine is working, the piston, heating up, expands and, as if between it and the cylinder wall, there will be no necessary gap, wedged in the cylinder. If the gap is too large, then part of the exhaust gases will break into the crankcase. Tse brought to the fall the vice in the cylinder and the change in the tightness of the engine.

Therefore, the piston head is made with a smaller diameter, lower seat, and the seat in the transverse section is not cylindrical in shape, but looks like an ellipse with a larger weight in a plane perpendicular to the piston pin. On the back of the piston there is a cut. Through the oval shape and rozrіz spіdnitsі zabіgає jamming of the piston during the work of the warmed-up engine. Zagalny annex The pistons are the same in principle, those designs can be drilled down depending on the features of a particular engine.

The piston rings are subdivided into compression and oil pumps. Compressor rings tighten the piston at the cylinder and serve to change the burst of gases from the cylinders at the crankcase, and the oil pumps remove excess oil from the walls of the cylinders and prevent the penetration of oil into the combustion chamber. Kіltsya, prepared from chavun chi steel, mayut rozrіz (castle). The number of pockets in different dviguns can be different.

The piston pin hinges the piston from the upper head of the connecting rod. The finger of preparations looks like an empty cylindrical shear, the outer surface of which is hardened by high-frequency strumas. The axis of the moving finger in the piston bosses is surrounded by steel rings.

The connecting rod serves to connect the crankshaft with the piston. The connecting rod is made up of a steel shear of an I-beam, upper and lower rose heads. The upper head of the installation has a piston pin, and the lower head is attached to the connecting rod pin of the crankshaft. To change the rubbing at the upper head of the connecting rod, a bushing is pressed in, and the lower one, which is made up of two parts, is fitted with thin-walled bushings. Offset parts of the lower head are creaked with two bolts and nuts. Oil is supplied to the heads of the connecting rod for an hour of operation of the engine. In V-like engines, two connecting rods are attached to one connecting rod of the crankshaft.

Kolіnchastiy shaft vygotovlyaєєєєєєєєєєє єєєєєєєєєє і sаlі or vysokomіtsiy chavunu. Vin is made up of connecting rod and root pins, pins and counters. The rear part of the shaft is shaped like a flange, which is used to fasten the flywheel with bolts. On the front end of the crankshaft, a belt pulley is fixed and a star is attached to the drive of the rozpodilny shaft. The pulleys may have an integration of a torsion damper. The design is the most widened - two metal rings, connected through the spring core (guma-elastomer, oil in the viscosity).

Quantity and refinishing of connecting rod pins to lie in the quantity of cylinders and refinishing. Connecting rod journals of the crankshaft of a bugatocylinder engine are in different planes, which is necessary for a uniform drawing of working cycles in different cylinders. The cores and the connecting rods of the neck are shackled between themselves with cheeks. To change the central forces, which are created by the cranks, on the crankshaft there are counters, and the connecting rods of the neck are crushed empty. On top of the root and connecting rod necks, gargle with high-frequency jets. The necks and cheeks have canals, which are designated for the introduction of the oly. The skin of the connecting rod has an empty hole, which means that the function of the dirt trap is impaired. At brood catchers, olia should be found in root necks and, when wrapped around the shaft, particles of brud, which are found in oil, under the influence of water center forces, water is cremated in oli ia and settle on the walls. The cleaning of the mud traps is carried out through the screwed-on ends of the threaded plugs at the ends of the threaded plugs only for the disengagement of the engine. The movement of the shaft in the later straight line is separated pucks. At the points where the crankshaft exits from the crankcase of the engine, there are oil seals and seals that help the oil flow.

At the engine, the thrust on the connecting rods and the root necks of the crankshaft is much greater. To change the rubbing of the necks of the shaft, they are rolled up in forged bearings, like vykonans in looking metal inserts, covered with an anti-friction ball. Inserts are made up of two halves. Connecting rod bearings are installed in the lower pink head of the connecting rod, and the main ones are at the block of the bearing cap. The caps of the main bearings are screwed with bolts to the cylinder block and stop, so that the self-door can be closed. So that the bushings are not distorted, their lugs are loose, and in the caps, saddles and heads of the connecting rods - give way to them.

The flywheel changes the roughness of the robotic engine, making it easier to start and smooth the car's rolling motion. The flywheel is made from a massive chavun disk and fastened to the crankshaft flange with bolts and nuts. When prepared, the flywheel is balanced at once from the crankshaft.

In order to ensure that the balance is not destroyed when the engine is being disassembled, the flywheel is installed on an asymmetrically reamed pin or bolted. In this way, yoga is incorrectly installed. For some engines, for lowering the torsional wheels, which are transferred to the checkpoint, two-mass flywheels are installed, which have two disks, spring-loaded between them. Disks can be shifted visually one by one at the radial straight line. On the front of the flywheel, marks are applied, with which the piston of the first cylinder is installed in the T.M.T. when installing the priming or the moment of the cob supply of fire (for diesel engines). Also, the gears of the crown, the appointments for hooking with the Bendix starter, are attached to the obid.

In order to change the vibration in row engines, the balancing shafts are installed, they are ruffled under the crankshaft at the oil pan.

The crankcase of the engine is driven at the same time from the block of cylinders. The details of the crank-and-rod and gas-spring mechanisms are attached to the new one. To increase the stiffness in the middle of the crankcase, there are ribs, in which the sockets of the root bearings of the crankshaft are bored. From below, the crankcase is closed with a pan, stamped from a thin steel sheet. Piddon vikoristovuetsya like a reservoir for olії that protects the details of the dvigun from the zabrudnennya. At the lower part of the sump there is a plug for pouring engine oil. The pallet is bolted to the crankcase. To protect the coil of the oil, a gasket is installed between them.

Malfunctions of the crank mechanism

Before the sign of the inadequacy of the KShM, one can see: the appearance of third-party knocks and noises, a fall in the tightness of the engine, promoted vitrata olії, overheated paliva, appearing dima in the gases.

Knocks and noises in the engine are blamed on the wear of the main parts and the appearance of large gaps between the received parts. When the piston and cylinder are worn out, as well as when the gap between them is increased, a metal rattling sound is caused, which is good to hear when the engine is cold. A sharp metal knock on all modes of the robotic engine indicates an increase in the gap between the piston pin and the bushing of the upper head of the connecting rod. Increased knocking with a sharp increase in the number of wrappers of the crankshaft to indicate the wear of the liners of the main or connecting rod bearings, moreover, the knocking is more of a dull tone indicating the wear of the liners of the main bearings. With a great wear of the inserts, it is possible to sharply fall on the pressure of oil. In this mode, the engine cannot be operated.

Falling tautness of the dviguna is due to wear or sagging in the grooves piston rings, wear of pistons and cylinders, as well as filthy tightening of the cylinder head. These malfunctions are caused by a drop in compression in the cylinder. The compression is checked for the help of a compressor to a warm engine. For this purpose, the mustache of the candles is turned, and on the plate one of them is installed the tip of the compression meter. When the throttle is open again, the engine is rotated by the starter for 2-3 seconds. In this rank, the mustache of the cylinders is consistently re-verified. The value of compression may be in the ranges assigned to the technical data of the engine. The difference in compression between okremi cylinders may exceed 1 kg/cm2.

Increased oil vitrate, overheated paliva, appearing dim in the exhaust gases (with normal oil level in the crankcase) sound when the piston rings are stuck, or the piston rings and cylinders are worn out. You can put the ring on without disassembling the engine, pouring a special fire into the cylinder through the opening for the candle.

Due to carbon deposits on the bottoms of the pistons and combustion chambers, the thermal conductivity decreases, which causes overheating of the engine, a decrease in pressure, and an increase in heat loss.

Cracks in the walls of the cooling shirt to the block and the cylinder head can appear as a result of freezing of the cooling core, filling the cooling system of a hot engine with a cold cooling fluid or after overheating of the engine. Through the cracks in the blocks of cylinders, the country, which is cold, can be swallowed into cylinders. What color exhaust gases become white.

1 river

Kolіnchastiy shaft zvnіstі vіdpіdaє nazvі, oskіlki sladєєz kіlkoh kolіn, raztashovannyh on one axis. Kolіna tse great ledges folding form, vіdlitі єdinim tsilim іz shaft. The number is designated for fastening the connecting rods, on which the pistons are fastened to their line. Krim Kolіn at the shaft є іnshі elements. Nasampered, chains, that are cylindrical support spacers between the knees, which allow the shaft to be stiffened at the cylinder block.Kolіnchastiy shaft in the process of operation of the car is added to that dvigun, in the way of installations. Therefore, it is not recommended to rearrange the kolіnval, which is used in living in the next block.

The filthy fastening of the shaft did not immediately turn around for a long time, to which the necks were ripped throughout the whole year, creating a support point. Supports for the neck of the shaft allow it to wrap around. For this, the necks are spiraled on special bearings, for which there are no rollers. Cі bearings are called root bearings. The role of the sack or the rollers is to win the oil, like a continuous stream flowing in the space between them and with the supporting necks.  To ensure the rotation of the connecting rods, the design of the crankshaft has other bearing journals, which are called connecting rods. On the vіdmіnu vіd korіnіh, stinks roztashovanі not on the same axis with the root collars, but on the side. The leather shaft length is made up of two ribs and one neck, on the lower end of the connecting rod as a “clothing”. , rushing uphill and down, squeeze the necks on the connecting rods and shake the shaft around. This is how the transformation of the reversible movement into a wrapping takes place. Krim klin with connecting rod journals of the crankshaft of the main counterweight for the replacement of excess oil to the shaft. Some of the most important elements can be revealed by guessing what Medium swedishness Wrapping the crankshaft for an hour of operation of the engine is approximately 3000 revolutions per stroke. Kolіnchastiy shaft - part of a folding form. So that the important knees did not create a ruinous vibration during the wrapping, the skin from them and vrіvnovazhené their counteragogue.

To ensure the rotation of the connecting rods, the design of the crankshaft has other bearing journals, which are called connecting rods. On the vіdmіnu vіd korіnіh, stinks roztashovanі not on the same axis with the root collars, but on the side. The leather shaft length is made up of two ribs and one neck, on the lower end of the connecting rod as a “clothing”. , rushing uphill and down, squeeze the necks on the connecting rods and shake the shaft around. This is how the transformation of the reversible movement into a wrapping takes place. Krim klin with connecting rod journals of the crankshaft of the main counterweight for the replacement of excess oil to the shaft. Some of the most important elements can be revealed by guessing what Medium swedishness Wrapping the crankshaft for an hour of operation of the engine is approximately 3000 revolutions per stroke. Kolіnchastiy shaft - part of a folding form. So that the important knees did not create a ruinous vibration during the wrapping, the skin from them and vrіvnovazhené their counteragogue.

If you want to use the mind of high accuracy with the rotation of the crankshaft, the minimum battle with the wrapping is inevitable. For the same reason, the oil seals of the crankshaft are the same for Zaporozhets and Mercedes.

In the middle of the body of the crankshaft there are special channels for supplying oil to the roots connecting rod bearings and special empty ones, closed with stoppers, to catch the debris and the particles present in the oil. For the help of the system, the shaft, when wrapped, is softly woven at the points of fastening, we clean it clearly. engine oil. During the repair of the crankshaft, the plugs are opened and cleaned of the empty pipes and channels of the oil supply with further blowing through under a vice.  On the back end of the shaft lathe turn the flange, in which there is a central opening of the bearing, which is the support of the gearbox input shaft. The flange can also be opened from the grooves for attaching the flywheel. In front and behind the crankshaft, which shifts the revolution of the oil in quiet places, at the end of the flywheel, the name of the cylinder block comes out. Krim dviguniv internal fire, and navіt until they appear piston engines, compressors, pumps, in press installations and other mechanisms, the crank mechanism is deactivated. Colinshaft shaft - a part for the skin dvigun is unique, and it is possible to rearrange it from one dvigun to another, but it is not recommended. On the dermal motive force, the knee shaft is milled in its own way, and the milling of them lies in the milling and number of cylinders, the working cycle, the length of the piston stroke and other parameters.

On the back end of the shaft lathe turn the flange, in which there is a central opening of the bearing, which is the support of the gearbox input shaft. The flange can also be opened from the grooves for attaching the flywheel. In front and behind the crankshaft, which shifts the revolution of the oil in quiet places, at the end of the flywheel, the name of the cylinder block comes out. Krim dviguniv internal fire, and navіt until they appear piston engines, compressors, pumps, in press installations and other mechanisms, the crank mechanism is deactivated. Colinshaft shaft - a part for the skin dvigun is unique, and it is possible to rearrange it from one dvigun to another, but it is not recommended. On the dermal motive force, the knee shaft is milled in its own way, and the milling of them lies in the milling and number of cylinders, the working cycle, the length of the piston stroke and other parameters.

Material and preparation of the crankshaft

For the preparation of the kolіnchastih shafts vikoristovuєtsya alloyed that carbon steel or high chavun. For the preparation of forged bell-shaped shafts, vicorous steel is either alloyed with carbon steel, and for lithium - high-grade globular chavun, malleable pearl chavun or steel is alloyed. Procurement for shafts is either cast or hot stamped.Kolіnchasti shaft - a great detail with the accuracy of the swiss years

Processing of finished blanks in a mechanical way on verstas is made up of low operations: roughing, finishing, finishing and finishing. At the same time, the accuracy of the mechanical processing increases the pressure on the cold editing of the shaft in the process of mechanical processing. At the connection with the folding configuration of the crankshaft, a number of operations are carried out on four automatic plots, on special benches. Tse vikonannya tsentruvannya and pіdrіzuvannya ends, drilling otvіnіn, obrobka korіnnih and connecting rod necks, grinding, dynamically balancing.Kolіnchasti shaft or, as it often seems to motor vehicles, "kolіnval" - tse one of the most important (and not only beyond the scope) and other important details daily dvigun. The wine is located in the lower part of the cylinder block, from the bottom of it, the crankcase is closed - the dvigun pan, filled with engine oil.

Yak looking

As you can see from the photo, this element can be finished in a folding form. Yogo basic warehouse partsє:

- root necks;

- connecting rod necks;

- chocks;

- counters.

Core (support) necks serve to support the crankshaft in pro "beds". The stench does not cling to the process of robots and bearings, like a wrapper. Shards on the root neck fall more navantage, their diameter is larger, lower in connecting rods.

Connecting rod pins (knees) - all supporting surfaces of the connecting rods. In order to improve the order of the robotic cylinders, the knees are shifted according to the axis of the wrapping of the songs of the kuti.

If the crankshaft is constructed in such a way that there are bearings on the sides of the skin of the connecting rod neck, the veins are called full-supported, otherwise - incompletely supported. Modern automobile engines of the largest width may have the most fully supported wheels.

Kolіna z'ednаnі mіzh schokami. The countervails, which are the prodovzhennymi schіk at the bіk of the protivolezhny kolіn, vrіvnovazhuyut vіdtsentrovі forces, scho vinikayut when wrapping. In the middle of the crankshaft there are oil channels, for the help of which there is a oil of connecting rod pins.

From such materials, that is how it is prepared

The material and technology of production should be determined by the class and recognition of the car:

- For standard production cars kolіnchasti shaft vіdlyvaєtsya z chavun, tsim reach mіnіmalna sobіvartіst vіrobnitstva.

- Kolіnval natuzhnіshіh i sports cars forging and fabrication of steel. Porovnyannі z chavunnym vіn may have improved characteristics for such parameters as dimensions, weight and weight.

- The most expensive option, which is victorious in luxury models, is a kolіnchasti shaft, twisting from a solid piece of steel.

The space for the transition of the cheek at the neck is the most important, because the maximum stress is concentrated here. Schob rozvantazhiti z'ednannya, yogo wink with a round transition (galtell). As a rule, zhalobniks shy away from the underbelly with the industrial technological belt. Such a constructive solution allows saving the maximum value of the active area of the necks - the surface under the liners.

Itself through the vindication of high navantage at the rears, not knowing the wide stasis of the shaft of the warehouse structure, at the same time the parts of the windings are fixed between themselves.

Why is it necessary

For the help of the crank mechanism of the engine, the reciprocating rotation of the pistons of the engine cylinders passes from the overhead rotation and is transmitted through the transmission to the wheels of the car. Kolіnchastiy shaft yakraz i is necessary for that, schob vikonati such a transformation. When working, the skin from the pistons of a chotiritactic engine is constantly found in one of the cycles:

At the phase of the working stroke, the piston is connected to it by a connecting rod, and that one replaces the crankshaft in its line. This is how wrapping is realized. Coming in order of the robotic cylinders of the engine, the piston at the same time squeezes the combustible sum and after the ignition of the stock, its connecting rod, after which the crankshaft uninterruptedly wraps around.

Flywheel

To the rear, as if marveling at the side of the belts / lanyards, the mechanism of the gas vent, the end of the crankshaft through the flange behind the additional bolts, the flywheel is fastened - a massive chavunny disk with a pressed toothed screw (divine photo). In order to prevent the flywheel from being distorted and the balance from being damaged, the centering pins were transferred or special bolts were rotated asymmetrically. To stop the flow of oil, an additional seal (oil seal) is installed on the flywheel flange.

The flywheel accumulates energy, which is necessary for driving the equal wrapping in the spaces between the combustible sums in the cylinders and driving the pistons dead spot(extreme upper and lower positions of the piston in the cylinder). The flywheel gear is connected to the starter gear. When starting the engine, the flywheel is turned by the starter, pushing the cob wrap shaft. Nareshti, itself, through the flywheel to the nodes and the transmission units, the overhead rotation is transmitted.

Start checking the correctness of the installation of the gas phases under the flywheel and the marks that indicate the position of the first piston at the upper dead point.

Shkarpetka

At the front part of the crankshaft, called the “shkarpet”, pulleys or gears are installed to drive the gas-discharge mechanism, elements of the cooling system and other units (divine photo). The scarf is reinforced with a ring cuff (omentum). In addition, from the outer side of the toe in the krishtsi of the dvigun, a pilovidbivach is installed, which breaks the penetration of the crankcase.