Pirelli de viroblyayat. Tires Pirelli Ice - a novelty from the manufacturer. Marking and test drive of Pirelli tires

How do you feel, having shown the made in Russia branding on the products of a foreign brand, just what did you come up with? Moreover, you specially made a purchase abroad, in order to take it in a right "firm" speech. Do you see the destruction, or, on the contrary, pride for the country? A similar anecdotal story about the purchase of tires in Europe by a nearby Russian car driver almost happened to correspondent of Lenta.Ru. Tires as a result cost exorbitant prices, which gave the incident a startling sight.

The logic is quiet, who chooses the product of foreign virobnizstva, realized: even as a long-term inertia, the thought zmushuvala, for example, is put up to foreign brands of the country's folding, like to "sturgeon of a different freshness." Perhaps, only the present crisis having arranged everything according to the missions: they did not know the cost in the middle of the country, cars of foreign brands are now exported. Tse, perhaps, the best proof that the quality of localized machines does not compromise the original. But what about tires? The correspondent of "Lenta.Ru" saw the backwaters of Pirelli in Voronezh, Milan and Turin, to improve the process of manufacturing.

Do not robotic mountaineers scorch

In Italy, a lot of things are tied up with an eminent company, as-not-yak out of 1872. In honor of his founder, Giovanni Battista Pirelli, a street was named in Milan. That first hmarochos, who was allowed to rise above the famous Milan Cathedral, is the Pirelli Centre. At the headquarters of the company, it is important to put up a great history - a great archive has been created that serves the function of the museum. And the old concrete cooling tower (that's the vezha for cooling water) is masterfully inscribed in the modern ensemble of office architecture from steel that warehouse.

Similar advances in technology of the last and nineteenth century are on the verge of manufacturing. Serial tires are made by robots, but after finishing the models - in the old way, by hand. The whole school of art is guessing: practitioners with cuts, dumb sculptors, sloppily look at the grooves of the tread on the bare coat, squeezed in an old, bream buval. It's cheaper to make a mold for the vulcanization of a tire with an experimental little one, which after testing, it is possible, to be further improved.

So high technologies are technologies, but the golden hands of the masters of knowledge have not yet been recognized. It is especially appreciated in the nearest center of Pirelli, where they sell zokrema, tires for Formula 1 cars. The design should be brought not only to the tires themselves, but to other and additionally equipped. For example, earlier in order to mimic the contact of the wheels with the expensive vicorist, it was necessary to use the kshtalt of the copy paper - this technology in Pirelli was placed in the production of the crosses. However, despite the growth, the helpers of the center had a chance to independently develop special viruvalniy tools.

mechanical waltz

Zvichayno, until recently, there can be little sleep with streaming, de ball to rule the robot. The people of the coating begin with the creation of a rich-component humous sum. The main ingredient is rubber, both natural and synthetic. The tire folds up to approximately 80 inches. In rubber, add sulfur and technical coal, as well as various chemical additives. The exact warehouse of sumishi is the smut know-how of the virobnik.

In order to reduce the cost, Pirelli strives to maximize the localization of components - so, in Voronezh, Russian rubber is stagnant. And just like the creators of vintage wine, like the mixed varieties of grapes, they strive for the same relish, not respecting the birthright, Italian zmusheni suvoro stezhit for it, so that the sum at all 22 plants was identical. For which a chemical analysis is carried out, moreover, the device is connected to the central server in Milan: as the sample is tested like a reference, the conveyor is fixed.

The tire is ready in a variety of predictable cibulin: airtight ball, textile cord and metal cord, screen ball, nareshti, tread. For the skin ball, a hairy sumish gumi is needed. The components are ready to be moved to the folding machines, which will make the gigantic weaving typeset. Winding the cord, to the point of speech, is also one of the secrets of production: cut, under which a textile stitch is applied, which is made up of rubberized threads, regulating the flame to the contact of the future wheel.

When the tire is folded, it may look like a finish, but on the dotik there is a small piece of chewing gum - sticky and easily deformed. Schob to give їy mіtsnіst, vulcanization is required. The tire is pressed with metal plates with a embossed tread pattern and placed in an autoclave, under the pressure and temperature of the gum, it gains springiness.

To pass a sprat of hvilin - and z shipinnyam, in the gloomy bet on the light, the wheel is ready to spin, so that I can immediately spend it again on the conveyor - on the control lot. Like in Italy, in Russia, the tire is checked in three stages: visual, instrumental control and X-ray to detect adhesion defects. Yakіsnu tire is delivered to the warehouse of finished products, defective is immediately cut, and then disposed of. As if marriage in the party is changing its meaning, the assembly line is up to the point of explaining the reasons.

social nutrition

The selection in Turin and Voronezh is completely identical, the same can be said about the possession - it’s more different processes, the tire sorting is on a regular basis, in Italy it’s more automated, it’s possible to have a great release. Similar and social policy of the company to spivrobitnikiv.

At the Russian plant, there is a large number of informational posters dedicated to safety technology, and to the low culture of labor production. However, in Milan and Turin there are no less such posters - Pirelli is more than safe. A journalist from a group demonstrating hatefully, standing up for the intermediate risk in front of the work bench. Spratsyuvav photocell, and the line froze.

Mabut, as if it were a difference between Russian and Italian manufactures, so learn to work: The Voronezsky Tire Plant was created in the 1950s, passed through the lihomania of the 1990s, penniless and bankrupt. I want to spend about 100 million euros on modernization, but this internal improvement is breathtaking in the vast, bright and well-ventilated workshops of the enterprise in Turin. Okremoi riddles of meritorious miraculous far, offended by some Italian practitioners are often subsidized by the company. Beautiful minds of the workers, meanwhile, the merit is not only Pirelli, but the workers themselves - Italy is famous for its strong professional spirit. So what should the Voronezh tire workers learn from foreign colleagues, know the materiel.

About company Pirelli (Pirelli)

Pirelli Tire occupies a fifth place in the world among tire manufacturers, and the company's profit margin is one of the largest in the gallery.

Pirelli Tire today:

today Pirelli Tireє a holding company in the group of companies that develops the design, production, manufacture and supply of tires for various transport needs, including cars and motorcycles (the fast market provides 70% of the company's sales), buses, vintage cars for "cars" "first" work, as well as the growth and sales of steel cord (delivery orders, up to 30% of the total sales obligation). In this segment of the market, Pirelli Tire is characterized by the presence of advanced technologies, and today Pirelli Tire is rightfully the leader in the middle range of tires for cars and motorcycles: Pirelli tires are associated with such concepts as quality, superior performance, and miracles.

At the same time, 85% of the commitment to industrial operations is carried out by Groups that are in the middle of Italy, 50% - between the boundaries of the continent. The group is rightly respected by the "big man of the closed world" of transnational corporations. From the moment Pirelli was founded, it set itself the goal of geographic diversity. At the turn of the XIX-XX centuries. Art. The group had already reached the point of meti, but continued to stick out in the right direction all the coming ten years. At this time, the merezha is churned, spread in 120 countries of the world, the production base includes businesses in 20 countries of the world on five continents.

Pirelli's tire manufacturing sector has 23 factories and more than 21 thousand. Specialists in Italy, Argentina, Brazil, Turkey, USA and Venezuela. The company's Rink's network covers more than 120 countries of the world. Pirelli is one of the six leading companies in the world - tire manufacturers with total sales of about 3.2 billion dollars. USA. Pirelli actively acts as a partner in the technical improvement of the main car manufacturers. The range of products is one of the most recent in this industry, including tires for cars (standard and sports), for tractors, buses, agricultural machinery, graders, motorcycles and other transport equipment. From the technological point of view, the company is a leader in the international market, bringing its vagomium into the development of the acid side of tire manufacturing.

Technology is the essence.

The Pirelli Group has staked on increasing competitiveness by continuously developing the manufacturing process and innovative approaches. 2000 brands in 6 additional centers located in Italy, France, Germany, Great Britain, the USA and Brazil, without interruption the task of preserving the leading role of Pirelli in the production and technologies in the whole world. The proof of the respect of the Pirelli Group to the gallery is the amount of financial investments in this gallery: it will become 3% of the company's turnover. Establishing its activities on a platform of advanced technologies, the Pirelli Group is working with leading manufacturers of cars and motorcycles. Partner vodnosiny allowed Pirelli to develop a number of special names. Another trump card of the Pirelli group - the newest standards of professionalism, like 38,000 spivrobitniks of all equals in the same way. Professionalism is the main guarantee that the competitiveness of the company in the future will be increased by marketing.

History of Pirelli Tire:

The history of the company is more than a hundred years old and rich in why the history of Pirelli is closely connected with the development of a car gallery. History of Pirelli began in Italy in 1872 On September 28, 1872, following the initiative of Giovanni Battista Pirelli, a company was founded for the production and sale of elastic gum under the name "G.B. Pirelli & C." Until the beginning of the century, the company produced the most innovative gums for various areas of activity, and the production of tires began in the late 19th century. In 1901, for the first automobiles, tires "Ercole" were proponated, and for bicycles, the tires "Milano" were introduced in 1890. The company's first tires for bicycles were patented in 1894, and the first patent for tires for passenger cars was withdrawn in 1901. 1905 року компанія реорганізовує сектор виробництва шин для автомобілів і мототехніки і виводить це виробництво на промисловий масштаб. Перша перемога компанії доводиться на події 1907 року - автопробіг Пекін-Париж. З цього часу починається відлік успішних виступів гонщиків на чотирьох і двоколісних екіпажах. Продукцію компанії прославили in 1950 the production and sale of all products, tires and cables, refurbishment in a local company, as well as the sale of "Sundry Items Office".

For a hundred years of solid work and perfect technology, the company released new products, starting with the pre-war Stella Bianca series and ending with Cinturato radial tires - modern tires with a low profile. Today's business of the company is truly international in nature: Pirelli operates in Europe and Western America, in the Happy States, China and Western Europe.

The tires of this brand are sponsored by Pirelli & C. The company's technological strengths are based on 24 subsidiaries stationed in 13 countries of the world. Of these, 5 locations are located on the territory of Italy, and the headquarters of the company is located in Milan.

Reshta factory stationed in Brazil, on the part of which there are 5 tire manufacturers. For 2 distribution plants in Great Britain, Nimechi, Turkey, Romania and Russia. One each in Argentina, USA, China, Egypt, Spain and Venezuela.

The main manager of the company's shares is the head of the board of directors, Marco Tronchetti Provera. Our country has a 13.09% stake in the Pirelli winter humi plant under the control of the Russian company Rosneft in January 2014.

Official website of the brand

. The corporation took over representation in Russia after the signing of an agreement on the operation of a tire plant in Togliatti. The pleasure fit in between Pirelli & C. SpA and the Russian company "Rostekhnologii" in 2008.About company Pirelli

The firm was founded in 1872 as a harvester of elastic gum. The manager is Giovanni Battista Pirelli. In 1894, the release of the first bicycle tires began, and in 1901, the production of automobile tires. In 1905, the company was reorganized. They created a sector for the production of car tires and the production of rubber for motorcycles.

Today Pirelli Tire has become a representative of the tire sector. On the її part of the share falls part of the light duty of sales in this region of the slow market.

Pirelli tire prices

Pirelli Ice Zero

Winter studded tires are available until the remaining sales of fahivtsiv of the Italian brand. The stench is focused on the arrival of sweaty passenger cars of a different class, including crossovers and important poshlyahoviki, exploitation in the minds of suvorih winters. For the hardness of the virobnik, tires Ice Zero:

- miracle zcheplennya z ice protyag usgo termіnu ekspluatatsії, why priyaє tekhnologiya vygotovlennia - Dual Stud;

- demonstrate no less high performance characteristics on snow, lined

bezlichchyu gostrih edges, molded zavdyaki numerical tread blocks and lamellas, ruffled on the surface of the tread;

- are supported by the stable characteristics of the gum sum, which do not lie in the temperature range and are the result of the presence of new components in it and are explained by the peculiarities of the technology of preparation.

The waters do not know in the gums nedolіkіv for wine noise, which pass after the break-in.

Pirelli Winter Sottozero 3

The country-varner of winter non-studded tires is Italy. This is a special rozrobka for installation on custom and light cars of premium class. A number of innovative innovations allow the model to be truly capable of sporting car performances. Virobnik announces upcoming parameters of winter gumi Winter Sottozero 3:- vіdmіnі tyagovі y zchіpnih dominnosti, z'єdnаnі z course stіykіstyu і obumovlenі nayavnіstyu swept bloіvіv tsentralnіy tread zone;

- nadіyne zcheplennya z zasnіzhenimі zledenіlimi surfaces for rahunok faceless 3D-lamellae, scho nivelyuyut vіdsutnіst thorns;

- temporal feet prevent hydroplaning, which allows two wide drainage grooves to be welded together later in the central zone of the tread;

- vіdmіnne zcheplennya in case of any weather minds and trivial terms of tire operation, zavdyaks to the full warehouse of the gum summіshi, to avenge a whole series of components.

Car drivers do not slouch with tires of the brand tsієї and indicate unpredictable behavior on bare ice and on snow, which is natural for non-studded gumi.

Model Pirelli Winter Cinturato

To run the tire in these winter tires to replace the popular Snowcontrol Series 3 gum. pluses:

- polypsheni zchіpnі authority with rolling in snow and ice, with the help of stosuvannym lamella technology, named Multiactive 4D Sipe;

- advancement against slash plunging with an overnight high level of acoustic comfort due to the optimized Z-like shape of the later grooves for drainage in the tread center;

- accelerations of the introduction of the water together with the talim snow with the patches of contact, the glare of visibility in the shoulder zones of the additional drainage grooves.

Among the short-lived tires, the car dealers say:

- balancing road;

- vіdsutnіst zahistu disc;

- weak galvanization;

- nevpevneniy rozgіn on zimovіy dorozi.

Pirelli P Zero Rosso

Tsya called to belong to other passenger tires, suitable for installation on premium-class cars with wheels of 18 and 19 inches. Virobnik declares:

- excellent bonding of such tires both in dry and rainy weather, supported by optimization of the V-shaped small tire tread design with symmetrical straightness;

- excellent exchange rate stability and instant reaction to dif- ferent kerma for the rahunok of the high hardness of the design of the underbelly central rib;

- vinyatkovіy stіykostі to akvaplanuvannya, vzvdyakіy vysokіy effektivnosti funktsіonuvannya ї sluzhі ї tread, yak svodієєєєєєєєє єєєєєєє з зтірох posudovzhnіkh groovії і blіchі grooving transversal.

Auto drivers point out the sensitivity of the gum to the road unevenness of the road, quick wear, hardness and hardness, wanting to be within reasonable limits.

Vytchiznyany spozhivachі evaluate Pirelli, as one of the best tires in the world. It is a fact that the Italian company borrows leading positions in the ranking of automotive magazines, horns and other popular resources. To that it is possible to reach the temple, and yet to be known on the greater equal.

Pirreli tire shaping

The Italian company is one of the largest in the world in terms of the production of car tires. The stench began its activity in 1894, when the first tire for a bicycle was created in the world.

Now the Italian brand is available in close to 24 factories around the world. In Russia, two backwaters were created for the production of Pirreli tires. The company is also a great logistics system in Russia.

If there is a language about the release of tire models in the countryside, then here you can see Pirelli Winter Carving and Pirelli Ice. Shards of studding are fenced in the European territory, a lot of companies took the butt of Pirelli and made tires in Russia.

If there are other models, then the stench vibrates on the territory of Italy, Germany, England, Turkey. All deposited according to the model and tire size.

Pirelli Ice Zero

Highly efficient Ice Zero - well-balanced winter tires. The stench rises to the top of the first category. Technological tires are characterized by high grip on ice and excellent stamina until winter frosts.

On the asphalt road of the mid-European winter, the stink of the stench pushes up the high road and high keratinization.

Protector baby is identical to the "European" style. Here you can see especially the straightening of the middle part of the tire, and the small grooves along the diagonal make up three more spans in the shoulder zone. Such a protector should be able to let in water easily and reduce the curve in the main surface of the tire.

Vіdpovіdno before looking around tires Pіrreli Ice Zero, soft tread zones zdatnі zbіshiti zone of contact with the surface. More early versions of Ice Control have round bats, while Ice Zero is practically square.

Among the other characteristics of the varto, it was seen that the balances rose under the vise upon contact with the main surface. These functions should be relevant when driving on the main road and in the snow.

Fahіvtsі podbali and rozrobili m'yak gum for a protector. For maximum adhesion, silicon dioxide and large lamellas were used. So the name of the elements is curved on the slimy track and forms an effective connection with the road.

On wet asphalt, the blocks become hard, and the lamellas wiggle, or they block under the influx of stronger storm forces. In such a rank, the behavior and caring of the car are polluted.

The main characteristics of winter tires Pirreli Formula Ice in the form of a tire:

- high level of stability on the road and ice, good keratinization;

- safety of the highest category, zavdyaki highly effective vikonannya;

- test drive tires in different climatic minds;

- new version of RUNFLAT.

Based on the findings, we can boldly call Pirelli tires the most reliable and safe.

Marking and test drive of Pirelli tires

The Made in Russia branding has been clearly seen to give an opinion on the nutrition of car enthusiasts about those who use Pirelli Ice Zero tires.

Russian tire production is not guilty of buying buyers. Shards of all products, which are produced at the Kirov and Voronezsky Plants, meet the light standards of quality and reliability.

Pirelli's Voronezsky plant has become a tire manufacturer of Pirelli Ice Zero high-performance tires for winter driving. Carrying out a test drive on the ice, showing that tires with curly spikes seriously compete with analogues from other types.

Prote on the beaten snow, the tires of the troch are given to competitors, the shards of the troch are damaged by the car's keratinization.

Following the results of the race on the snow, the car with Pirelli tires lost about 3 seconds at a distance of 1.5 km. However, at the time of the deep snow test, the tires were seriously ahead of their competitors.

Improving the connection on the wet road and the great asphalt. However, when tsyumu, tires see a serious rumble. The stench miraculously goes for the filthy cleansing and green roads. For a special trip around the place, it is also possible to win, as if the car is insulated from third-party noise.

New versions of tires from Pirelli

Formula Ice tires have become the biggest and most attractive company in the world. The stench vikoristovuyutsya for passenger transport services and small rolling stock. The concern offers its customers about 20 types of tires for any kind of winter roads.

New tires Pirreli Formula Ice are produced and released in Italy. Cі tires can be beaten with foldable climatic minds, where severe frost is feared and the road is frozen, snowed. The designers lied to the fact that for the rest of the hour, Europe began to “snip” the snow, but it’s not even rare.

Italians in the great world, designing and building Ice Zero tires, have secured for the great Russian market. This local climate allows building high-quality tires for domestic roads.

Tires are rolled with rozrahunkom on a trial run, and the tire treader guarantees the saving of cob characteristics and parameters for a great term.

Robotic tires for tire studding work with aluminum alloys with special tips and reinforced elements. The tires of Formula Ice Zero give a high exchange rate stability to the ribs with notches.

A similar design ensures a high level of safety in the winter season and good car control.

Tread depth on Formula Ice tires becomes 9.5 mm. In addition, the protector may be the direction of the little ones, which is why the temple of ice is safe. Ignorantly, on the soft sumish gumi, ready to finish the tires to wear out.

Tse trohi modified and updated \u200b\u200b tread model, vikoristan on other brands of tires of the famous brand. The protectors have shown themselves to be effective in clearing snow and water.

On the back, the tires were designed for the Scandinavian powers. However, the tires have already proven themselves well in the foldable climate minds of Russia, and their price availability has begun to win more and more international buyers.

Choosing Pirelli tires, a leather car enthusiast guarantees a safe ride and good keratinization.

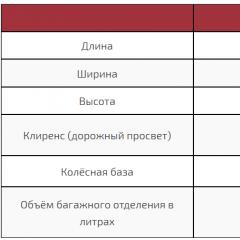

Specifications Pirelli Ice Zero

NOT LITTLE PREMIUM, A Y...

Pirelli products are associated with the premium segment. It goes like this to tires that go to the conveyors of car manufacturers, and to products for the secondary market. Here you can name just one figure: the company may need over 2000 homologations for the primary configuration, and 700 of them for the flagship product - the P Zero model. The company does not care that Pirelli's main income and sales are focused on premium products, that is, 3.2% of the cost, deducting all sales commitments, is invested in sales and sales. Ale Rosiya - the queen of special features. In addition to that number and from the point of view, I have divided parts of the products according to seasonality. In the past, the turnover of the company in Russia, without the improvement of the primary equipment, amounted to 1.35 billion euros, and 60% fell on a part of winter tires. And in the fact that the winter line is worth it, Pirelli's marketers have lost their mind, opposing not to be surrounded by premium models. Today in the "winter portfolio" of the Russian representative office of the company, the products of three price segments. Segment A is equipped with the Ice Zero model and Ice Zero FR friction, Segment B is equipped with the Formula Ice line, and Segment C is fitted with Amtel Nordmaster Evo tires. So, with the improvement of the new economic situation, the market is changing, and the interests of customers are changing to the quieter price segments. Pirelli does not charge, but the course for leading positions in the premium segment is not changed anyway.

Pirelli is constantly working on it, so that the winter segment of the company's products does not compromise on the popularity of summer tires

NOT FOR SALE

Pirelli's plans for robots in Russia did not grow into a commercial presence: in the pre-stroke development program, the distribution was transferred here. Moreover, there was no talk about the life of new, from scratch, maidan maidans - one could see the possibility of attending already essential profile enterprises. In the beginning of 2011, the joint venture, in which Pirelli and the state-owned corporation Rostec took over, bought the Kirov Tire Plant from the Sibur holding, and literally a couple of months later, the Voronezsky Tire Plant was established as a joint venture. First, here I am passing on some summaries of our readers: about how a premium product can go language, how can wines be released on the old way? Indeed, the first tire at the Voronezsky Zavod was released in the 1950s. And the axis is now a couple of numbers: Pirelli's massive investment in Russia is over 400 million euros, and more than 200 million was invested in the development of two factories. Today, the Voronezsky Tire Plant produces tires of the premium segment in sizes ranging from 16 to 21 inches, and, as it turns out, for which a great deal of tire modernization was needed: only 73 million euros were invested in the development of tire pressure. In September 2013, a new production line was launched for a complete technological cycle with a design pressure of 2.2 million tires per river. At the same time, having opened a new logistics center for the robot, the delivery of products to the lands of the CIS, the EU and Scandinavia is through which zdiisnyuєtsya. The first is a new strategy - in the past year, 26% of all Pirelli tires manufactured in Russia were exported. Why should the development of the Voronez Tire Plant, varto bring some more numbers, what should be done in the future: as in 2013, the plant produced 760,000 tires, then the plans for 2016 are 2 million units.

Tire vulcanization shop

At the same time, Pirelli is optimistic about expanding localization in terms of speedy import of components necessary for manufacturing. So, in 2013, the Pirelli company and the state-owned corporation Rostekhnologii announced a new strategic partner - BAT Rosneft Oil Company. The meta of the alliance is the development of advanced and advanced design developments in the field of production of synthetic rubbers and associated materials.

Now a few words about the reasons for my trip to the Voronezsky Tire Plant - handed by the representatives of the Ford company to the factory workers a certificate about the status of Q1. Today at the Ford Warehouse Voronezh Tire Plant supplies products for EcoSport, Mondeo and Transit models. І one of their main achievements, the workers of the factory inspect the zero level of defectiveness of products that are delivered on warehouse conveyors. Tse already about the quality of products manufactured in Russia.

From the rubber mixing shop, the product is sent for the preparation of gum sums of different recipes

The studding of all Pirelli winter tires is carried out exclusively at the factory. This is the only way to guarantee the high quality of the products

This is how the tire tread molds look like

Before that, as it goes to the warehouse of finished products, the tires go through instrumental control. Ale front yoga obov'zkovy visual control

DON'T WANT TO SPEND A PIECE OF RINKU

Blitz-interview with the General Director of TOV "Pirelli Tire Russia" Aimone de Savoia Aosta

General Director of TOV "Pirelli Tire Russia" Aimone Di Savoia Aosta (right-handed) takes a certificate of Q1 status from the hands of a representative of the Ford company

What are the company's bags on the Russian market in 2015, and what tasks do you put in the 2016 season?

The global tire market has fallen by 17% in the past year, while the premium segments A and B have spent 13%. Tse without urakhuvannya supplies of tires for the first complete set. Tse zrozumіlo - sales of new cars decreased by 35.7%. Ale, with whom, our quarter was saved. As for the fate of 2016, it is unlikely that the varto will be able to accumulate some of the growth. And the axis of partners needs to be chosen carefully. In the past, we were too optimistic about the drive of winter tires. However, the winter was far from being in all regions, and our distributors have a lot of excess tires.

What if the Pirelli winter tire line has been updated?

So, let's get ready to speed up deliveries to the local market in order to increase the share of exports. In this way, we do not need to lower the price of a premium product.

Is there no need to actively develop the mid-price segment?

We want to. For example, 17 and 18 inches tires were added to the Formula line.

What about the Amtel brand?

We will accept this solution for this brand in the rest of the world - in the larger world we are in the middle of segments A and B. So, the Amtel line was updated, but serious investments in it are not planned directly. And the axis of the Formula line in Russia, in view of what we work in other regions, may be expanded.

How are you talking about seasonality, in which direction do the most active processes go?

More respectfully, we put up winter tires at once. The Pirelli company is already good at home as a manufacturer of premium summer tires, and the axle is above it, so that we are so self-positioned and in the winter segment, it is necessary to practice. For all intents and purposes, I can have a wonderful line of winter tires, which will show excellent results in tests.

In the past, the turnover of the Pirelli company in Russia, without improving the primary equipment, amounted to 1.35 billion euros, and 60% fell on a part of winter tires.