Yak vyroblyayutsya car tires in great factories. Automotive tire technology

Persha in svytі pіzі new tire The bullet was broken by Robert William Thomson in 1846, but the wine was not rooted in the middle of the world. The idea of a pneumatic tire was reintroduced in 1887, if the Scotsman John Dunlop thought of putting his 10-row blue on the wheel of his tricycle bicycle, wide hoops, broken from the hose for watering the garden, and inflate the others. And as early as 1890, the young engineer Chad Kіngstn Weltch propelled the camera out of the pokryshka, insert the pokrishka into the edges of the pokrishka, and put it on the side, as if he had already removed the dullness to the center. Todi f the English Bartlett and the Frenchman Didn't know how to install and dismantle tires. All this meant the possibility of storing pneumatic tires on a car.

1. The main materials for making tires are gum, which is made from natural and synthetic rubbers, and cords. Cord fabric can be prepared from metal threads (metal cord), polymeric and textile threads. The tire is stored from the frame, the balls of the breaker, the tread, the bead and the base part.

2. On the photo, you can use the maybutniy cord.

3. Unvolcanized huma is even more sticky, so you wander around in a bobbin with a gasket from special material, which allows you to easily remove it.

4. Blanks in such axle bobbins are sent to the warehouse. Plates with numbers - the size of the width of the cord.

5. Here the tread protector should be repaired. A line of gumi is refueled into the car, de-extrusion is transformed into a maybutny protector.

6. For a clear visual assessment of the size of the tire, the color of the brand is applied to the tread.

7. The board is allowed to sit tightly on the wheel rim. For the general purpose of the onboard rings and the inner ball in viscous anti-penetration (for tubeless tires) Gumi.

8. Drit from tsikh cat to come to the verstat, de curl up with huma.

9. At a number of versts, the rubberized drum should be twisted to the required diameter and drawn in circles.

10. Come out from the side of the board, which is the basis for the operation of the whole board.

11. Board climb here. The crumbs below you will see the process.

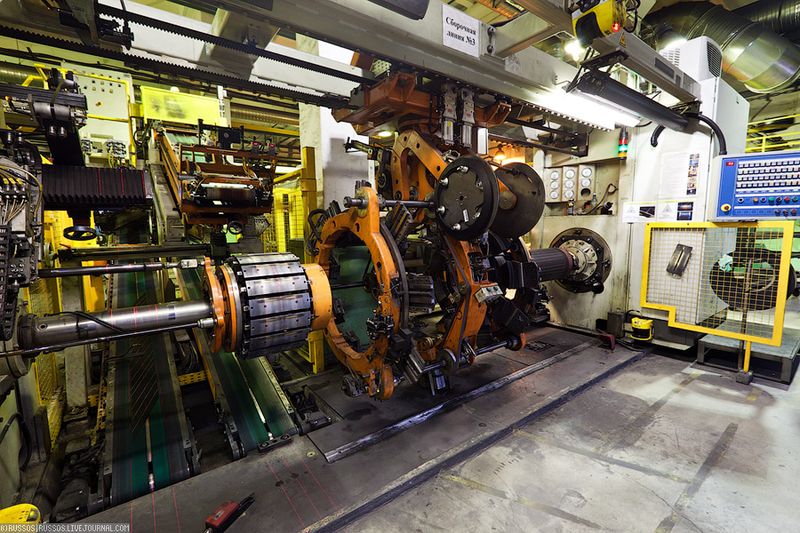

12. Nice step - folding pokrishki. All the necessary workpieces are suitable for the verstat.

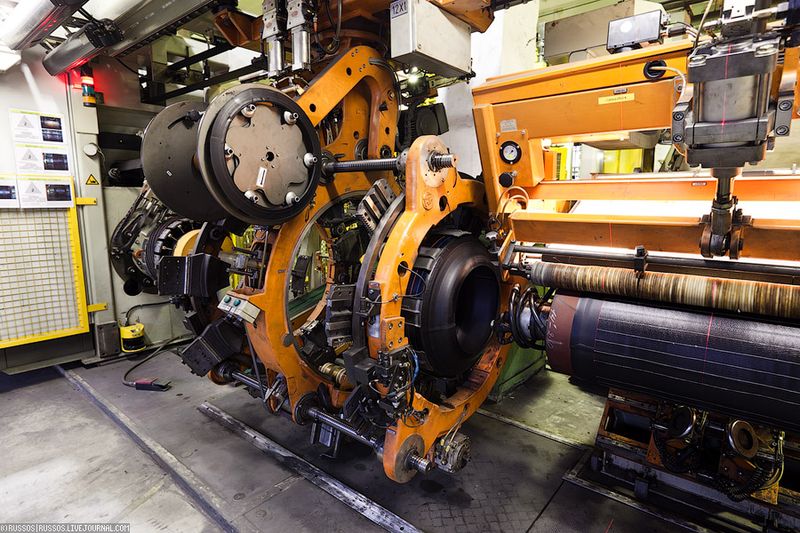

13. Verstat for the class "Glory to the robots!" Warehouse for only onboard plates.

14. And let the apparatus ruin everything by itself: win picking all the components of the coating and blowing the workpiece over and over again before the protector with a breaker.

Bagato avtovlasnikiv may be more aware of the budget of car tires, but also about those, how to ruffle tires, there is little that is possible. It is more widespread that the huma is poured into the yak form, and then the ready virib is pressed.

However, this is not the case, but the production of car tires is a folding, high-tech process, for which it is necessary to have a folding special possession, automatic automated control, and the fate of high-quality failures.

Trishki іstorії

The first gum tire was blown back in the distant 1846 by Robert William Thomson. At that time, the wine driver didn’t get stuck, and again, before the pneumatic idea, the tires turned around 40 years later, since in 1887 the Scottish John Dunlop came up with hoops from a watering hose, and put them on the wheels of a bicycle and put the blue on the wheel.

Three times later, Charles Kingston Weltch, having proponated the camera and pokrishka, inserted a dart into the edges of the pokryshka, and put them on the backside, as soon as he had shaved off the pile to the center. At the same hour, the rationalization methods for assembling and dismantling tires were pro-proponated, which made it possible to freeze gum pokrishki on cars.

Tire production process

Why be timid

The main material, which is used for making tires, gum, is prepared on the basis of natural rubber. Due to the fact that in some proportions and some kind of rubber is added, in the end bag there are summer or winter car covers.

So, in a gum sum for lithium tires to get more and more piece rubber, so the huma goes more hard, stiff to wear, it is not "fiery" at high temperatures and will not get better on the road surface. schob vigotoviti winter pokrishki, To add natural rubber, which rubs the humus more and more softly and elastic. Zavdyaki tsomu winter tires do not "dub" navіt in severe frosts.

- Krym rubber in gum sums to add non-ligating components, such as plasticizers, napovnuvachi, soot, vulcanizing additives.

- The tire is stored in decal elements, combined in one unit: a frame, a textile twine, a breaker ball, a tread, a bead and a core part.

Yak timid frame

Cord maybutnoy pokrishka rocking from metal, textile or polymeric threads on a special verstati - "spool". From a helpless cat, the threads converge in one piece. The zagalnyi rice has a construction of a weaving verstat. The distance of the plexus of the cord is consumed in the extruder, so that it can be removed from the rubber.

The ready-made carcass is ready to open on smogs of a sizeable width, for the production of tires of sizeable size. I roll into reels for storage and transportation. Oskіlki unvulcanized guma is even sticky, so it is uniqueness of the frame with the balls inserted into the gaskets.

Yak timid protector

The offensive stage virobnitstva - the stem of the protector. The line of the rubberized cord is filled in verstat, which by the method of extrusion transforms it into the tread. Sob, the workers could visually clearly visually increase the size of the maybutny pokryshka, on the protector of the headlamp they could use the color lines.

The offensive stage virobnitstva - the stem of the protector. The line of the rubberized cord is filled in verstat, which by the method of extrusion transforms it into the tread. Sob, the workers could visually clearly visually increase the size of the maybutny pokryshka, on the protector of the headlamp they could use the color lines.

Side part

The side of the pokrishka is stored from the side ring and the ball in viscous overpowering gumi. The repair of the tire beads is due to the fact that the metal oxide is trimmed, because of what the necessary radius is twisted. wheel disc and use colas. Writing at the verstat, the fold is coming. You can watch the video in detail about the process.

zbirka

Perestann_y stage - folding of the finished pokrishka. Get out at the verstat, for which all the ready-made elements are needed. There are two handlers to service the verstat: picker and recharger.

The first one inserts the side rings, and the other inserts the bobbins with the components. When the number of versts is set, everything is robbed automatically: one piece together and blowing out the workpiece over and over again is the protector with a breaker. Mayzhe ready to tire zvazhuyut and look for the presence of defects. The whole process can also be admired on the video.

vulcanization

Ostann_y stage virobnitstva - volcanization. The tire is covered with a hot steam under a 15 bar grip at temperatures close to 200 degrees per Celsius. As a result, rubber, soot and all kinds of additives stick together, and on the surface of the coating, behind additional press forms, tiny tread and writing are applied. The tires are ready to be converted to suit the required characteristics.

The technology of tire production is repaired from the outset for additional special computer programs for small modifications of the tread and the profile of the tire. Behind the help of the program, you will be guided by the behavior of the skin pokrishka options on the road in different situations. For what, those tires, they showed best results in model road tests, hand-drawn at the verstat and pass the test in real road minds... Instead of the technical indicators of a skin test tire, compare with the shorter indicators of those of a similar class, if you need to go through the update and start up in a series of virobnits.

Etapi car tire production

1. Vyrobnitsvo gumovy sumishі

The first stage of the stem of the be-like pokrishka polyaga gum sum, Warehouse which is at the skin company-virobnik is individual and is stored in the suvoriy taumnitsa. To be amazed at the same time, it’s the same as gumi shini to lie down like this technical characteristics, Yak:

- r_ven zcheplennya with a roadbed;

- hope;

- work resource.

Syrovin and vitratic materials

The technology of tire production is inimitable in the absence of any new components, materials and chemical components without such components. In given statistics, they are overwhelmed by the main components.

Everything can be reached by the workers of the robotic chemistry, who are choosing, combining the components and the components in the humus, according to the most reasonable and computer data. As a rule, it is the correct addition of the components to lay down the quality of gumi, so it’s not a secret for anyone, and it includes the offensive components:

- rubber, which forms the basis of gum sum, which can be synthetic or more expensive isoprene. As a practice demonstration, Russian rubber will be used to grow into the world and until the whole day will be victorious to be used by the most popular foreign companies-virobniks for the preparation of our products;

- promislovaya soot, won’t be technical soot, which gives a characteristic color of humus, and is suspicious of its merit and weariness, as the soot itself appears to be molecularly cured in the process of vulcanization;

- silicic acid, yaka є an analogue of soot in prepared tires by foreign vyrobniki and advancing the level of pokryshka on wet roadway;

- oils and resins, such as additional components and the role of gumi softeners.

- vulcanizing agents, zokrema sirka and vulcanizing activators.

2. Vibrating tire components

Tire technology of transmission is such a stage of production of components in a tire, which is a series of such parallel processes as:

3. Collapsing of car coating and vulcanization

Tire picking is the third stage of the process and is visually on the folding drum by the method of last application over one ball of the frame, bead and tread with the tire sidewalls, for which the vulcanization procedure is applied.

Technology of car tire production, video-overview:

Automobile tires for us are a very special item, which we do not think about the folding of their model. Until then, the tire can be mounted on the car, there are a number of processes. In the case of the skin splint, it is not the simple workers of the plant that take on the fate, but the helpless ones.

Shlyakh novoy shini from doslidnytsky center to vlasnikiv cars

Great corporations may include a number of thousands of sportsmen, a part of some of the most advanced science stages. Їх mainly come up with new look tread, wid the most recent viglyad how to lay down the quality of the road surface, the shaving of the car, the economy of the gasoline, the indicators of noise. An important place here is a warehouse of gumi, which is infused into the durability of the design.

Practically all the boxes can be found in special computer programs. Guidelines for the center to model the behavior of the tire and select the option good characteristics... Let us try to slow down the test images and see them in the Polish minds. Yakshcho new tire showed excellent results, lower models of the same class, then її run in a wide range. You can make corrections first.

Etapi car tire production

The leather car concern has its own fine wines, which do not want to be crooked. However, the main processes and the last are analogous.

Preparing gum sum

Warehouse of the sum at the skin company. Chemistry chooses the proportions and list of components in such a rank, so that they do not have the best performance in terms of operation and quality. Main warehouses of gum sum:

- rubber- the basis of be-like gumi. Can vikoristovuvatisya natural or synthetic walking. Bagato of foreign wines to buy rubber in Russia.

- promislova soot... In the same way they call technical coal. Vaughn will change the description and erase. The soot appears to be molecularly cured before the hour of vulcanization, and there is a special color of gum.

- silicic acid... American and European companies, due to the lack of natural gas for the production of technical carbon in their territories, began to use silicic acid. I can’t replace the industrial soot with silicic acid; Capture the heat from the wet surface. Behind the cordon, the speech is positioned, as an ecological component at the warehouse of gumi. Silicic acid for an hour of use of the tire is less stained and does not leave black deposits on the asphalt.

- Oils and resins... Before the warehouse comes in, you need to give the finished product the necessary level of zhorstkost.

- Vulkanizatsiynі activators. They include serka, zinc oxide, stearic acids. The smell comes out in the quality of the initiators and catalysts in the process of vulcanization, and also opens up a vast net of polymer molecules.

Preparing tire components

The components of the tire run on two main groups, which are displayed in parallel. To the first group, introduce a protector, a hermetic layer, sidewalls, to the other - side rings, metal cord, textile cord.

Car tire picking

A breaker, nylon bandage, protector will be wound on one drum one by one. On the other drum, put the side ring and apex together with the hermetic layer and sidewalls. For whom to offend a part of it, as a result, there is a "sira" bus. Vona povnistu ready before the offensive process.

vulcanization

At the special installation "Sira" the tire is inflated and churned under high temperature (170-205 degrees Celsius) and 22 bar grip. The value of temperature and pressure to lie in the form of the tire and can be seen in the guided parameters. At the final stage, combine all the components in one unclear whole. The hour of volcanization is close to 10 hvili. The tire is going to be called up to us.

Quality control

ready car tires look around the progress of the sportsmen, and then change the automatic machines. Products from vads should be disposed of and not consumed until after. The control of the quality can be changed and upon completion of the steps, for example, the warehouse of gum sum can be changed. The entire technological process is subject to machines and computers. Lyudin mainly quilts behind the robot of the great friends.

visnovok

The design of new tires is completed by the folding technological process. The prepared skin pads have had a lot of practical and scientific products. At the factory, the tire must pass through a series of stages from the end of the humus summit to volcanization. Before drinking, the quality of a skin splint is transformed by a human and a robotic machine.