Diesel engine 41 pos_bnik for repair.

Ratings

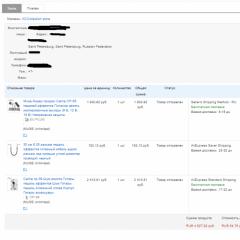

4Т6-04С9 - Set of original inserts.

The shaft is used for completing the A-41 diesel engine and modifying engines on its basis. Apply a certificate of conformity to the purchasing (new) drive shaft and check the generator terminals, as well as the postman terminals on the shaft housing. When transported and stored, it is necessary to protect the working surfaces of the crankshaft and protect them from thermal (do not overheat), mechanical (

don't hit, don't be trashy ), corrosive (do not wet) and other damage. Crankshaft journals are produced in nominal sizes.

Repair of the A-41 crankshaft is carried out by high-class mechanics with great confidence in the work

|

suchasne obladnannya |

. |

The nominal and repair dimensions of the shaft are indicated in tables 1 and 2. The plant transfers a variety of connecting rod and main journals to the shaft. |

||||

|

The virobnik indicates a large group on the 7th shaft. |

If the drive shaft leaves the factory with the 1st nominal marking on the journals every day. |

The virobnik indicates a large group on the 7th shaft. |

If the drive shaft leaves the factory with the 1st nominal marking on the journals every day. |

The virobnik indicates a large group on the 7th shaft. |

If the drive shaft leaves the factory with the 1st nominal marking on the journals every day. |

|

|

0,127 |

0,038 |

|||||

The generator plant balances the drive shaft in dynamic mode.

|

suchasne obladnannya |

. |

In this case, the imbalance becomes a little more than 160 rubles. |

The nominal and repair dimensions of the shaft are indicated in tables 1 and 2. The plant transfers a variety of connecting rod and main journals to the shaft. |

|||

|

The virobnik indicates a large group on the 7th shaft. |

If the drive shaft leaves the factory with the 1st nominal marking on the journals every day. |

The virobnik indicates a large group on the 7th shaft. |

If the drive shaft leaves the factory with the 1st nominal marking on the journals every day. |

The virobnik indicates a large group on the 7th shaft. |

If the drive shaft leaves the factory with the 1st nominal marking on the journals every day. |

|

|

104,98 |

0,022 |

0,137

|

0,048

|

|||

|

104,73 |

104,75 |

5,625 |

||||

|

104,48 |

104,5 |

5,75 |

||||

|

104,23 |

104,25 |

5,875 |

||||

|

103,98 |

||||||

|

103,73 |

103,75 |

6,125 |

||||

Table 1. Connecting rod journals of the crankshaft

Marking of size groups

Diameter of crankshaft journals, mm Thickness of the insert, mm

1.2. The oil dispenser is pressed onto the shaft flange from the rear side. The bent side of the flange is turned at the side of the flange shoulder.

Stop the oil dispenser with a way to press the metal of the oil dispenser into the sinkhole (along the sinkhole) on the shaft.

The gap between the ends of the oil dispenser and the closed end collapsible shaft up to 1mm.

2. Vimogi down to the details that stick together.

2.1.

- By increasing the service life and preventing premature failure of the crankshaft.

- So even if you are not making claims, it is necessary to look into the details of the parts that are put together.

Parts that have been completely rejected do not allow installation

technical minds

CONTENT on defective parts of the A-41 engine.

2.2.

The shells of the connecting rod and main bearings correspond to the dimensions of the crankshaft journals (div. Table 1 and 2). Suitable for the set of connecting rod and main bearings: A23.01-93-41SB (41-03s4-2) - connecting rod tabs;

A23.01-116-41SB (4T6-04s9) - root inserts.

2.3.

The choice of diameter for the ring is based on the diameter of the 5th root neck.

2.4.

Static imbalance of the spindle shaft pulley is more than 75 rubles.

2.5.

Static unbalance of the flywheel in combination with oil and screws of no more than 50 g. 2.6. The caps of the main bearings of the forged engine crankshaft must fit neatly into the seating area of the block.

It is not possible to change the wheel position of the main bearings.

3.4.

Tighten the bolts securing the bearings, starting with the third main bearing, at which the tightening torque becomes 402-431 N m (41-44 kgf m).

3.5.

After tightening the bolts of the main bearings of the wheel shaft of the A-41 engine, the pressure in the bearings should not exceed 49 N m (5 kgf m).

The play of the (bottom) crankshaft in the bearing rings does not exceed 0.093-0.380 mm. For main bearings, the gap is set at 0.116-0.180 mm. 3.6.

Tighten the connecting rod bolts, starting with the long bolt to a torque of 216-235 N m (22-24 kgf m).

3.7. The constriction of the connecting rod along the crankshaft is as tight as “hands”.

The play (bottom) of the lower head of the connecting rod mounted on the crankshaft is between 0.24-0.70 mm.

3.8.

- After tightening

- connecting rod bearings

The drive shaft must rotate with force no more than 186 N m (20 kgf m).

4. Running in and testing of the A-41 engine

Respect!

The engine must be put into operation only after preliminary running-in. 4.1. Running in is necessary to ensure that all surfaces that rub are used. 4.2. The running-in of the A-41 engine is divided into stages:

1st stage – running in at low speeds for 1.5-2 years;

2nd stage – running in at nominal speed on a working tractor for 60 years. 4.3. Run-in is carried out in accordance with the factory technical documentation for the A-41 engine.

- 4.4.

- The running-in process is accompanied by listening to the engine, carrying out visual monitoring of the engine operation, whenever a malfunction is detected.

- 2 valves at the gas cylinder mechanism.

- The stationary flow unit has the designation 214A1, 7 = G304.

- The DS-8 is used for the winter, and the DS-11 for the fly.

- Solidification of the engine cooling system.

- 1.62 kWg – indicator of vitrati paliva.

- 412 Nm at 1300 rpm - it’s a matter of time to turn.

- 16 – display for the standard compression stage.

- 130 mm diameter at the skin rim.

- 140 mm increase the piston stroke.

- Cylinders installed vertically.

- The maximum number of cylinders is the same as 4. The indicator increases, as you can see, for example, engine ZMZ 41.

How the engine looks like 41

Engine A41: kudi yogo can be installed

Danish variety of aggregate present in:

- Pump installations.

- Grader.

- power station.

- excavator.

Connection with other types of equipment is allowed, as the representatives of the plant do not mind.

Vikorist engines on tractors of the T-4A, DT-75M, T-4 series.

The GAZ 41 engine also became popular.

Main features, overview information Since the engine is 90-horsepower, the new cylinder volume will be higher than 7.43 liters. Whenever the engine is running at low speeds, it becomes very painful.

Retailers are trying to keep up with the latest trends characteristic of motorcycle manufacturing.

Therefore, a system for uninterrupted persistence was introduced into the control system unit.

In the middle of certain parameters, the valves are rotated during the engine's operation when pressure springs are applied to them. This occurs through vibrations that accompany standard operating modes. Valve motors

are considered more reliable, so such a design can be added to the existing structure.

The most serious ambitions are expected to be spent on the split shaft.

Therefore, this hardening is conveyed by the solidification of high-frequency streams. The robot mechanism is ensured by 12 cams and 7 necks, which are located in the middle. Vuzol begins to collapse when interacting with the crankshaft.

Gear transmission takes part in this process.

Environmental friendliness

power unit

- - Another meal, something that the retail workers seriously thought about.

- The units that have come out of the production process do not destroy the waste streams into the atmosphere.

- Therefore, the oil system of the A 41 engine is no longer reliable.

- Due to modifications

It is important to note that depending on which special equipment is tested, various modifications of the engine are tested.

The main models will be as follows: On the DT-75 tractor, install A-41I, SI, S.

- For auto vans and rollers, A-41 D is suitable. A 41-G – modification for drilling rigs, graders, asphalt pavers..

- The station pumps pump stagnant water of the A-41 series.

- Tractor research in technology

- Basic models are more often installed on tractors or other equipment manufactured at the manufacturing plant.

- The engine is available in a total of 11 modifications.

- With additional equipment, the following is allowed:

Larger heat exchanger for the refrigeration system motor oil Pre-start electric torch heater.

Pneumatic compressor.

Jammer. Coupling coupling with modernization. Two hydraulic pumps instead of one. The adjustment of the cylinders of the modifications also varies.. The remaining models have a different layout, although some have up to 100

- Kin forces nominal tension increases. The torque reserve increases up to 20%, especially in the case of DT 75.

- Every day the engine is serviced on a regular basis.

Otherwise, the procedure is carried out every 8-10 minutes.

The tightness of the joints and fastening elements is checked regularly, cleaning from the saw and saw is carried out.

Watch carefully for outside noises, topping up the water.

The refrigeration system cannot do without regular maintenance.

- The system must be flushed using a descaling method.

- Additional sealing will seal if it leaks. The service engine needs to be repaired promptly Description of malfunctions

- Among the most widespread problems are the following:

- The engine overheats, making further operation impossible.

The cooling system of the unit causes stagnation of water.

This will lead to precipitation and the appearance of calcium deposits on the walls. The heating of radiators is important before temperature increases. Items should be carefully cleaned, scale removed, and then removed.

Sometimes it is necessary to replace the thermostat or pump that is faulty. Advice to Olya's child. For example, if the valve cover loses its tightness.Such caps are installed next to the skin group of cylinders. Ale in the remaining modifications

similar problems verified. Work with noticeable vibration.

In this situation you can’t do without revving up the engine.

After that, check the piston and crankshaft.

The best way to replace the bearings is to rebalance them if they are out of order, and this happens often.

Engine failures, starting problems.

Breakdown often appears through the filter, which is necessary for firing.

The persistence system also becomes a source of unacceptable inheritances.

The scorching system is being carefully looked around for the first time.

After this, the engine will be rebuilt.

Visnovok

10) - Piston pin;

11) - Connecting rod bushing;

12) - Piston ring;

13) - piston ring;

14) - piston ring;

15) - Sleeve;

16) - Kіltse ushchіlnyuvacha;

17) - Vinets;

18) - Flywheel;

19) - Bolt;

20) - Flange;

21) - Cuff;

22) - Bearing;

23) - Bolt;

24) - Washer;

25) - Maslyanka;

26) - Oil washer;

27) - Pivkilce;

28) - Krishka;

29) - Toothed crown;

30) - Connecting rod cap;

31) - Gear;

32) - gear;

33) - Oil washer;

34) - Bolt;

35) - washer;

36) - Pulley;

38) - Ratchet;

39) - Washer.

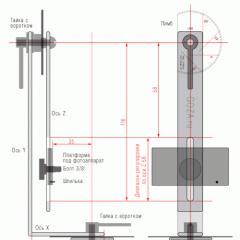

Colony shaft (1) [Fig.

5] pentaporny, steel stampings. The cranks of the collapsible shaft are rotated in the same plane. To ensure the wear resistance of the shaft of the neck, apply high-frequency strings. Sh The brass necks of the shaft are empty. The empty connecting rod journals, which are closed with threaded plugs (3), have a cleaning oil in the center that goes out from the main bearings through the same openings in the crankshaft.

To quickly clean the oil, roll tubes in the openings of the connecting rod journals to ensure that oil is taken from the central area of the empty connecting rod journal. At the front end of the crankshaft, splines accommodate gears (32) and (31) for the gas cylinder drive and drive

oil pump

V-belt pulleys (36) drive the fan and water pump.

Gears (31), (32), pulleys (36)

persistent puck

(39) the oil washer (33) is pulled to the end of the main journal of the crankshaft with a bolt (34) (tightening torque 300 N.m. (30 kgf.m)), which is fixed with a lock washer (25).

A ratchet (38) is attached to the pulley (36) behind the bolts (37), which is necessary for turning the crankshaft manually when adjusting the gas igniter mechanism and firing equipment.

H

The fourth cheek of the crankshaft is round in shape, there is a groove for installing a toothed screw (29) to the drive of the alignment mechanism.

The toothed end is pressed onto the joint shaft, first heated to 150 degrees Celsius, and further secured with bolts (3) [Fig.

6] through the thrust plates (6).

Small

6. Mechanism of the engine A-41 for tractors DT-75, DT-75M, DT-75B, DT-75K.

1) - Housing;

2) - Gear; and the rear end of the crankshaft has a flange for installing a flywheel (18) [Fig.

5] and oil washer (26). About

The entire movement of the shaft is surrounded by piston rings (27) - they are made from steel-aluminum stitches and are moved along the side of the rear main bearing.

The gap between the bearings and the worn-out collars of the crankshaft on the new engine becomes 0.095-0.335 mm.

The bearings are locked against rotation by pins that are pressed into the main bearing cover.

The two ends of the crankshaft (front and rear) are reinforced with rubber cuffs, which are installed in the grooves of the crankcase cover (5) of the secondary gears (2) [Fig.

2] that flywheel housing (16).

Small

2. Engine A-41.

Late cut.

1) - Oil pump;

2) - Column shaft;

3) - Front support;

4) - Motorcycle doctor;

5) - Gear housing;

6) - Fan;

7) - Water pump;

8) - Cylinder head;

9) - Inlet manifold;

10) - Kovpak;

11) - Clean the surface; 12) - Rozpodilny shaft;

13) - Krishka; 14) - Head coupling; 15) - Flywheel; 16) - Flywheel housing;

17) - Equally important mechanism.

13) - Krishka; Deposits

13) - Krishka;(2) and (5) the main and connecting rod bearings of the collet shaft are bimetallic and are made of steel-aluminum stitches.

To ensure optimal processing of the root tabs, tin the tabs. The dimensions of the inserts, which indicate the tension at the support (that is, the height of the protrusion of the surface of the socket of the liners above the surface of the socket of the support) are controlled using a special attachment.

For these liners, which are used as spare parts, it is allowed to place the upper and lower liners behind the total reference height of the liners. At this time, the inserts in the vus zone will be colored green and red.

When installing such inserts, they must be followed by the marks (red and green). Z

2) - Gear; clearances in connecting rod bearings for new engines vary between 0.096-0.16 mm, clearances in main bearings range between 0.116-0.180 mm when aligned directly perpendicular to the plane of the bearing.

For these liners, which are used as spare parts, it is allowed to place the upper and lower liners behind the total reference height of the liners. Set the gap for the middle main bearing to 0131-0195 mm.

2) - Gear; P

about the diameter of the main journal of the collet shaft and, obviously, the liners, according to their type, are divided into two types and repair sizes [table.

| 3]. | The range of standards for inserts 1H and 2H are optional (installed on new engines). | Inserts of other standards are repair ones, they are installed on the engines after proper regrinding of the main journals of the crankshaft. | |

| In accordance with the standards of the inserts, the parts of the shaft are marked according to the manufacturing standards [Table. | 4], and the designated shaft is stamped on the surface. | ||

| 41-0401-2 | 105(-0,023) | 88(-0,023) | |

| 41-0401-2 | and the engine is equipped with a multipart shaft and bearings of the same size group. | 105(-0,023) | 87,75(-0,023) |

| 41-0401-2 | Table | 104,75(-0,023) | 88(-0,023) |

| 41-0401-2 | 4. Marking of the collapsible shaft. | 104,75(-0,023) | 87,75(-0,023) |

Number (designation) of the shaft Marking to standard

13) - Krishka; Diameter of necks, mm

indigenous The compression rings (12), (13), (14) are made from a special chavun and in order to ensure the looseness of the rings in the piston grooves (12), (13), (14) are formed into a trapezoid shape with a thin upper surface (at 10 degrees).

Most importantly, the upper compression ring (12) is chrome plated and coated with a tin ball for excellent finishing. The other (13) and third (14) compression rings are secured with three ring grooves on the outer surface using a quick finishing method. D The oil rings are box-type with a groove along the outer surface, which creates two bands (belt width 0.5 mm).

To introduce oil from the cylinder liner walls into the crankcase (through the hole in the piston), there are cross grooves near the body of the oil rings. Pid

Most importantly, the upper compression ring (12) is chrome plated and coated with a tin ball for excellent finishing. oil rings

When installing such inserts, they must be followed by the marks (red and green). Radial expanders are installed. connecting rod(6) I-cut is made, stamped using 40X steel.

13) - Krishka; The lower head of the connecting rod has an oblique slot for the possibility of inserting/removing the connecting rod through the engine cylinder.

5] pentaporny, steel stampings. The cover of the lower head is secured with two straight bolts, which are secured with lock washers.

The last bolt is a close-fitting one, which means the position of the cap in front of the connecting rod. In order to loosen the bolts from the forces that stick onto the connecting rod, the stick between the cap and the connecting rod is aligned to look like triangular splines.

2) - Gear; The bolts are tightened to a torque of 180-220 N.m (18-22 kgf.m), starting with a long bolt.

The housing under the connecting rod bearings breaks off at the same time as the cap. For correct installation The caps of the mark on the lower head of the connecting rod will come together on the bottom.

What does a major engine overhaul include?

1. Replacement piston group(Sleeve, piston, finger, rings);

2. Replacing the main and connecting rod bearings;

3. Repair of the spindle shaft (grinding/polishing);

4. Repair of the cylinder head, adjustment of valve clearances, pressing and shaping of the cylinder head surface;

5. Repair of combustion equipment (replacement of injection pump plunger pairs, replacement of fuel injection nozzles).

Verification, adjustment on the stand;

6. Replacement of all rubber parts, gaskets, bearings;

7. Repair of pneumatic compressor;

8. Repair of turbocharger (for obvious reasons); 9. Running in the engine on a stand in 3 modes (cold, hot idling

, hot under navantazhennyam);

10. Farbuvannya.

Engine exchange!

Change your faulty engine to an engine from overhaul in just 1 day!

You pay for the repairs and pick up the repaired engine from our warehouse!

This is a great way to save your time!

Repair term

Regardless of the importance of repair, we will repair your engine in a period that does not exceed 10 days.

Warranty

For all engines that have been overhauled, we guarantee 6 months from the moment of removal.

Delivery If you are from another region, this is not a problem! We will promptly move you with a transport company handy for you or by passing transport to any region of the Russian Federation.

In this case, we will deliver the engine to the terminal cost-free

transport company

in N. Novgorod, you will only pay for interterminal transportation to your place.

The special equipment is made of high quality agricultural equipment; special vehicles are equipped with different power units.

One of these representatives is the A 41 diesel engine, produced by the Altai Motor Plant, manufactured near Barnaul.

- Technical characteristics

- A 41 is a series of four-cylinder naturally aspirated diesel engines.

- Their main purpose is operation in industrial and agricultural machines.

- A 41 is a clear, non-vibrating, durable unit, easy to operate and easy to maintain, and this characteristic of the A 41 engines allowed it to eliminate the need for companions.

- A41, knowledge of the DT-75 tractor:

- Technical characteristics of the A 41 engine in the stock version:

- Vaga engine A 41: 930 kg.

- Engine dimensions: depth 1425 mm, width 827 mm.

- Vikonannya cylinder block: chavunny BC.

- Feeding of fire: by way of direct upgrading of DP.

- Dovzhina piston stroke: 140 mm.

- Diameter of the framed cylinder: 130 mm.

- State rhubarb squeeze A41: 16.

- Develops: 412 Nm at 1300 rpm.

- Vitrata paliva: hv.

- 1.62 kWh Cooling system diesel engine

- A 41: ridinna. Vikoristovvane oil: DS-11 summer period

- , DS-8 charge.

- Engine generator: stationary engine unit 7 = G304, 214A1.

- Number of valves in the gas distribution mechanism: 2

- Hydraulic pumps: 2 gear pumps, driven by crankshaft via gear type transmission.

Stated engine life: 12 thousand engine years on the remaining engine models.

Where is the AMZ A-41 engine installed?

This motor is used to equip excavators, graders, power plants, pumping units, and other equipment as supplied from the manufacturing plant.

From this tractor you will drive on tractors T-4, DT-75M, T-4A. Look at the special features - Engine A-41 The 90-horsepower engine has a solid cylinder volume of 7.43 liters, which allows the base model A 41 to produce such power at very low speeds, around 1750. Following the trends in engine manufacturing, the manufacturers introduced the A 4 1 block

electronic system

middle-free persistence: the firing supply is completely controlled electronically. An important feature of the A 41 engine is its double-valve gas-propelled mechanism. The engineers worked on it to give the engine the highest possible efficiency factor, resulting in efficiency.

In order to make the unit as reliable as possible, A 41 high-quality chevron sleeves are used, the surface of which is finished using the apex honing method.

This increases the resource of the engine, together with a well-thought-out cooling system (however, the air also grows).

Investigators also commented on the environmental friendliness of the power unit: the AMZ engine, which is produced from the workshops, meets the industrial standard R 41.96-2005 for a variety of damage to all kinds of troublesome and erratic speeches.

Engine modifications

The engine is produced in various variations, intended for operation with special equipment.

Main models:

The basic model of the engine and modifications are installed on tractors and other equipment, depending on the manufacturer. There are more than 11 engine variations, which vary mainly additional possessions

- .

- You can put:

- two hydraulic pumps;

- the coupling of the coupling block has been modernized;

- jammer;

- pneumatic compressor;

pre-start electric torch heater;

larger heat exchanger for the engine cooling system, etc.

Modifications of the engine A-41СІ1, 02 and 03 are divided into one type of cylinders: the remaining part of the row arrangement, which is why the nominal tension of the engine that is being developed has increased to 1 00 forces, and the torque reserve is up to 20%, in the same area with twin cities.

The popular tractors of the DT-75 series, according to the factory catalog, are equipped with engines A 41I, SI, C.

Beginning in 2001, when folded, the engine was assembled with a wet head for large cylinder groups, which is why the reliability of the gas valve decreased and the consumption of the engine oil went downhill.

In 2003, a modification was made from starting with an electric starter, which increases the service life.

And in 2012, the crankcase block of the A 41 engine was replaced with licensed German crankcases, which made the engine even more reliable.

Block crankcase:

This is a double-disc coupling of a dry viconanny type.

The adjustment of the DP 75 gearbox with the A 41 engine must be carried out, if necessary, depending on the result of the check, approximately every 240 engine years.

In the future, it may also be necessary to adjust the valves of engine A 41. A gap of 0.25 ... 0.3 mm is allowed for both valves of this engine.

- It is also important to maintain the engine after the change is completed or before starting.

- The on-line service interval is approximately 10 engine years.

- The set of manipulations includes:

- cleansing the engine from the pond, the saw, which has accumulated;

- checking the fastening and sealing of the sticks;

- control of the presence of external noise;

- Check for leakage of the engine oil. The engine cooling system should also be serviced promptly. The set of service operations includes:

removing scale from the cooling unit, washing the system;

checking for leaks and sealing

- weak people

radiator, per consumption

- Typical faults

The power motor has typical problems.

- Overheating

As the coolant of the engine cooling system, it is mainly water that removes the calcium deposits on the radiator columns and sediment in the pipes and drains of the system.

- Therefore, you should regularly check where the radiator is located and flush it, especially if the engine is to be operated at high temperatures.

Sometimes, in advanced episodes, it is necessary to replace the pump if it is out of order, or the engine thermostat A 41 has stopped working. The vitrata of motor oil is abnormally high. The reason for this is a leaky valve cover, specific to the sealed cylinder group. To correct this shortcoming in new models, Vikoristan crankcase blocks are of German manufacture. Loss of engine tension, strong vibrations during engine operation.

The obvious reason is a defect in the crankshaft or pistons.

You should also check the balancing bearings; they may become damaged due to the need to replace them. Poor engine start, interruptions during hours of operation. The reasons for this could be a malfunction of the system or stubbornness or obstruction of the brood.

- burning filter

This operation is complex, which also involves the installation of outstanding new characteristics of the connecting rod engine and oil system.

- When trimmed, the engine can now produce up to 145 horsepower, while saving the standard engine life.

Flashing. This increase can be achieved simply by program manipulations, reprogramming electronic device

keruvannya dvigun.

Important: when it is necessary to install the productive nozzles, the parts of the standard parts may not fit into the fittings.